Due to their ability to enable precise and controlled movement in a variety of industries, linear motion systems are essential to contemporary industrial applications. This motion is made possible by two main solutions: linear guides and linear bearings. Depending on the needs of the particular application, each solution has advantages of its own. In response to the growing demands of automation and precision-driven industries, these components have developed over time to provide improved accuracy, durability, and efficiency.

The main differences in linear guides and linear bearings will be discussed in this article, along with differences in design and operation, load capacity and accuracy, environmental adaptability, maintenance needs, and how to select the best option for your application.

Understanding Linear Guides

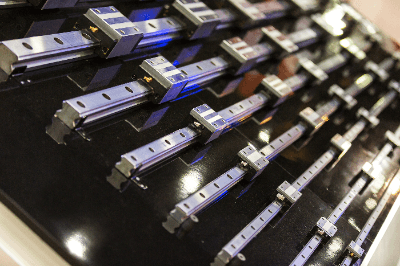

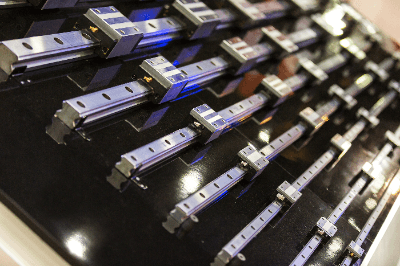

Advanced motion systems called

linear guides- also referred to as linear guideways or linear rails- are made to enable precise and seamless linear movement. They are made up of a carriage and a rail, low-friction motion is made possible by rolling components like rollers or balls. Applications needing mechanical rigidity, positional accuracy, and high load capacity frequently use these systems. Because linear guides can maintain precise movement under heavy loads, they are essential to industries like industrial automation, semiconductor manufacturing, and CNC machining.

Modern linear guides go beyond basic linear motion. They provide cutting-edge features like better stability, low deflection, and load distribution. Linear guides are perfect for applications where accuracy and durability are crucial because of their capacity to support large loads and provide precise motion. Long-term operational reliability and consistent performance are facilitated by their advanced design, which guarantees minimal wear over time.

Exploring Linear Bearings

Mechanical devices called

linear bearings are designed to guide linear motion along a shaft or rail while lowering friction. These bearings, which usually have an outer housing, inner sleeve, and rolling elements, offer smooth movement with a more straightforward and compact design. Applications like conveyor systems, material handling, and general automation that call for a moderate level of accuracy and simplicity of installation frequently use linear bearings.

Linear bearings, as opposed to linear guides, are made for simple applications where high precision is not necessary. Their adaptability is increased by their tolerance for environmental elements like dust and debris, and their reduced complexity makes them simpler to install and maintain. Linear bearings continue to provide useful performance in a variety of operation environments as industries place a higher priority on quick, affordable solutions.

Key Differences Between Linear Guides and Linear Bearings

- Load Capacity and Structural Rigidity: With their larger contact surface and sophisticated rolling mechanisms, linear guides offer superiors load capacity and structural rigidity. Even load distribution made possible by this design lowers stress and improved long-term durability. In contrast, linear bearings are less rigid under heavy loads due to their point-contact design, which limits their load-bearing capacity.

- Precision and Accuracy: Through their sturdy construction and minimal deflection, linear guides perform exceptionally well in high-precision applications. They are crucial for tasks requiring precise motion because they retain positional accuracy even when subjected to heavy loads. Although they work well for smooth motion, linear bearings are less precise and work better in situations where accuracy is not a top priority.

- Speed and Motion Efficiency: A combination of their less complicated design and reduced rolling resistance, linear bearings typically provide faster speeds. Applications requiring quick movement are best suited for them. Although they can achieve competitive speeds, linear guides are better suited for applications where controlled motion is crucial because they put accuracy and stability above maximum velocity.

- Environmental Adaptability: Since linear bearings can withstand dust, debris, and other impurities, they function better in challenging conditions. In contrast, linear guides frequently need extra protection in harsh environments in order to preserve peak performance and avoid premature wear.

- Maintenance and Longevity: To preserve accuracy and increase service life, linear guides need to be lubricated and aligned on a regular basis. On the other hand, linear bearings are more suited for applications where low maintenance is a top concern because they are simpler to maintain and usually need less frequent servicing.

Choosing the Right Solution for Your Application

A number of important factors, such as cost considerations, environmental conditions, and performance requirements, influence the choice between linear guides and linear bearings. You can make an informed choice that fits your operational requirements by being aware of these factors.

- Load and Rigidity Requirements: Linear guides are the recommended option for applications needing high load capacity and structural integrity. They maintain rigidity in dynamic environments and deliver reliable performance even under high loads. For simpler motion requirements, linear bearings provide a more cost-effective option and are appropriate for lighter loads.

- Precision and Accuracy Demands: Linear guides perform better if your application calls for precise positional accuracy, like in CNC machinery or semiconductor manufacturing. Although they work well for less exacting jobs, linear bearings are better suited for general-purpose applications where perfect accuracy is not necessary.

- Environmental Conditions: Linear bearings offer superior resistance and durability in settings with dust, debris, or possible contamination. Unless they have extra sealing and protective features, linear guides work best in hygienic and controlled settings.

- Speed and Motion Control: Because of their simple design and low friction, linear bearings are perfect for high-speed applications. Although they can reach competitive speeds, linear guides are a better option for applications that need precise motion management because they provide better control and stability.

- Budget and Maintenance Considerations: For applications where high precision is not needed, linear bearings provide an affordable and low-maintenance option. Long-term dependability and better performance in demanding tasks are offered by linear guides, despite their higher cost and need for frequent maintenance.

Future Trends in Linear Motion Systems

Both linear guides and linear bearings are changing to meet new challenges as industrial automation progresses. Enhancing durability, incorporating smart sensors for real-time monitoring, and creating environmentally friendly lubrication systems are the main areas of innovation. In order to meet the various demands of the industry, the next generation of linear motion systems will place a higher priority on energy efficiency, predictive maintenance and greater customisation.

You can select the best option that improves effectiveness, dependability, and long-term performance in your application by carefully evaluating your operational needs and comprehending the distinctions between linear guides and linear bearings.

For those seeking professional assistance or specialised expertise in dealing with linear motion systems, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our extensive

linear products selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Hubungi Kami

Hubungi Kami