Products & Services Industry Guides

In modern manufacturing, robotic arms have emerged as indispensable tools driving efficiency, precision, and innovation across a myriad of applications.

From automotive assembly lines to electronics manufacturing and beyond, the versatility of robotic arms continues to revolutionise how products are designed, produced, and delivered to consumers worldwide.

This article explores the diverse range of applications for robotic arms in the manufacturing industry, highlighting their transformative impact on processes, productivity, and quality assurance.

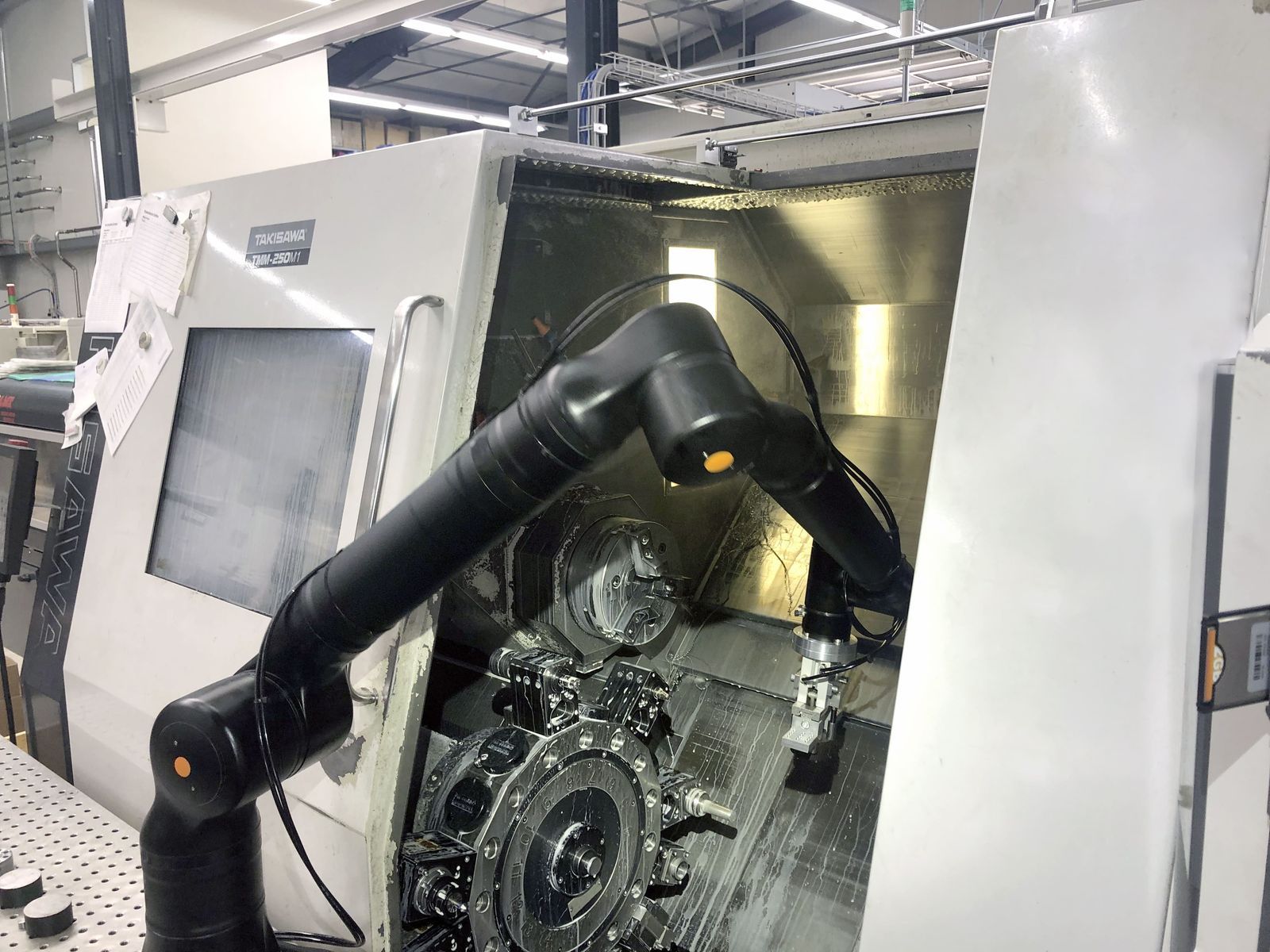

Several types of robotic arms are utilised in the manufacturing industry, each tailored to specific tasks and applications such as articulated robots, collaborative robots, SCARA robots and Cartesian robots.

Robotic arms play a pivotal role in assembly line automation processes, offering speed, precision, and flexibility in performing a wide range of assembly tasks.

Here's how robotic arms operate in assembly line automation:

Task Planning and Programming: Before deployment, engineers program robotic arms to perform specific assembly tasks using specialised software. This involves defining the sequence of movements, grasping techniques, and interaction with other components or machines along the assembly line.

Sensing and Perception: Robotic arms are equipped with sensors such as cameras, proximity sensors, and force/torque sensors to perceive their surroundings and interact with workpieces accurately. These sensors provide real-time feedback on the position, orientation, and quality of components, allowing the robot to adjust its movements accordingly.

Pick-and-Place Operations: Robotic arms excel at pick-and-place tasks, efficiently transferring components and parts from one location to another along the assembly line. Equipped with grippers, suction cups, or specialised end-effectors, robotic arms precisely grasp, lift, and position components with accuracy and repeatability.

By leveraging the capabilities of robotic arms in assembly line automation, manufacturers can achieve higher productivity, efficiency, and quality in their production processes.

Aside from assembly line automation, robotic arms play a pivotal role in material handling and packaging as well.

Here's how robotic arms operate within material handling and packaging operations:

Packaging and Labeling: After assembly, robotic arms handle the packaging and labelling of finished products, preparing them for shipment or distribution. Robotic arms pick finished products from the assembly line, place them into containers or packaging materials, and apply labels or seals as required, streamlining the packaging process and ensuring consistency in product presentation.

Material Handling and Logistics: In addition to assembly tasks, robotic arms are utilised for material handling and logistics operations within the assembly line. They transport raw materials, components, and semi-finished products between workstations, storage areas, and conveyors, optimising workflow efficiency and minimising downtime.

Robotic arms play a crucial role in quality inspection and testing processes by leveraging their precision, to ensure the accuracy and reliability of manufactured components or products.

Here's how robotic arms operate for quality inspection and testing:

Visual Inspection: Robotic arms equipped with cameras and vision systems perform visual inspection of components or products to detect defects, anomalies, or deviations from quality standards. The robot captures images or video feeds of the inspected items and analyses them using image processing algorithms to identify surface defects, scratches, colour variations, or dimensional inaccuracies.

Surface Profiling: Robotic arms equipped with tactile sensors or 3D scanners perform surface profiling of components or products to assess their texture, roughness, or contour. The robot makes physical contact with the surface of the item, measuring its topography and capturing detailed surface profiles for analysis.

Non-Destructive Testing (NDT): Robotic arms equipped with NDT techniques, such as ultrasonic testing, eddy current testing, or thermal imaging, inspect components or products for internal defects, cracks, or flaws without causing damage. According to Bindt.org, The robot manipulates NDT probes or sensors to scan the inspected items and detect any hidden defects or abnormalities within the material.

In conclusion, robotic arms have transformed the manufacturing process, revolutionising efficiency, precision, and innovation across a diverse range of industries.

As technology continues to evolve, robotic arms will play an increasingly critical role in shaping the future of manufacturing, driving innovation, and unlocking new possibilities for automation and optimisation.

By embracing the capabilities of robotic arms, manufacturers can harness the full potential of automation, transforming their operations and staying competitive in an ever-changing global economy.

If you're uncertain about how robotic arms can enhance your operational efficiency and productivity, don't hesitate to reach out to our team of experts.

SLSPRO experts offer comprehensive services and provide tailored solutions and specialised services to meet the unique needs of clients across various industries

Get in touch with us for professional help and greater operational efficiency today!

Explore Kassow Robots' innovative 7-axis cobots for versatile industrial applications. Precision, safety, and modularity.

Find Out MoreExplore Kassow Robots' innovative 7-axis cobots for versatile industrial applications. Precision, safety, and modularity.

Find Out More

Contact Us

Contact Us