Industry News & Trends Products & Services

Deep groove ball bearings are crucial in reducing friction and providing smooth, high-speed rotation in machinery and mechanical systems.

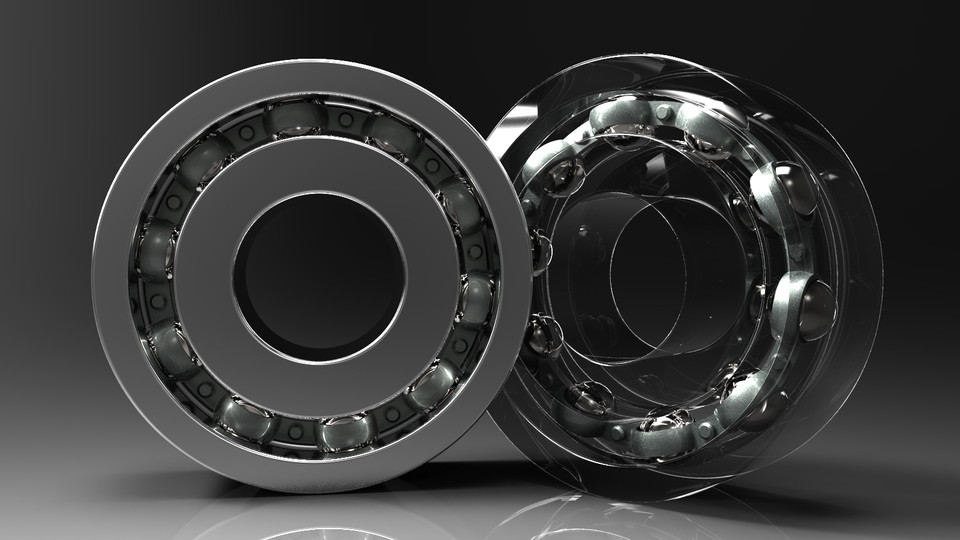

These bearings can be differentiated from other bearings by their deep raceway grooves on both inner and outer rings.

The deep groove ball bearings are made out of four components which include inner and outer rings, cage and ball bearings.

There are four main types of deep groove ball bearings which include single-row deep groove, double-row deep groove, open deep groove and shielded deep groove ball bearings.

In this article, we will explore the benefits of using deep groove ball bearings and what makes it a superior choice.

There are several contributing factors which ensure good quality and performance in deep groove ball bearings. Here are some key factors:

Steel grade: The durability and life of the bearings relies on the composition of the steel utilized.

Design conformity: A bearing can perform better if its dimensional accuracy is closer to the design standards.

Grinding: The grinding cycle ensures the smoothness of the bearing's inner and outer ring which is why it needs to be ground over many cycles.

Heat treatments: This process is essential to harden bearings, making them sturdier and long-lasting.

Deep groove ball bearings can be manufactured by a variety of materials to accommodate different applications. Here are more details on the different applications of the bearings:

Similar to other types of bearings, deep groove ball bearings can be mostly found in industrial machines as it is critical to the operation.

Ranging from gearboxes, internal combustion engines, construction equipment and agricultural machinery, the application of the bearings entails extensive usage in the engineering sectors.

Despite not being used in plain sight, most houses will surely have the deep groove bearing installed in their appliances.

Air conditioners, floor polishers, washing machines and even small hair dryers are some of the daily appliances which utilise deep groove ball bearings in their mechanism.

Offering several advantages over conventional bearings, deep groove ball bearings become the preferred choice in many applications. Here is what makes them a superior choice:

Enhanced and better radial load capacity: Conventional bearings do not have the heightened radial support that deep groove ball bearings do. Boasting superior radial-load carrying capabilities makes them a better choice.

Support bi-directional forces: The straightforward construction of deep groove ball bearings contributes to their ability to handle axial and radial loads in both directions.

High speeds: Deep groove ball bearings have a higher speed as compared to roller bearings because of the reduced contact between the rolling elements and the presence of raceways.

Improve load capacity: Because of the bearings' designs, less stress is imposed due to the equal transfer of the weight between races. This makes it suitable for heavy machinery equipment.

Versatile: Aside from heavy machinery, the deep groove can also be found in domestic applications such as refrigerators, motors, fans and pumps as it can reduce friction with minimal noise.

Easy maintenance: Several design characteristics make their maintenance relatively easy such as shields and sealed which protects them against contamination. It is also built with multiple lubrication options which requires very minimal maintenance over time.

In summary, deep groove ball bearings stand out as the optimal choice for efficient operation across different applications.

When considering where to purchase your best option, SLS Bearings emerges as your premier choice with our array of selections.

We are committed to providing deep groove ball bearings that meet only the highest standards, and you can browse them on our website!

Get in touch with us for help from our experts or the right bearings for your application!

Essential components ensure smooth and efficient rotational motion in machinery.

Find Out MoreEssential components ensure smooth and efficient rotational motion in machinery.

Find Out More

Contact Us

Contact Us