Linear motion is at the heart of many robotic applications. It enables precise and efficient movement in a straight line. Understanding linear motion begins with the concept of the initial position, which is the starting point of an object's movement. Whether it's manufacturing, healthcare, or logistics, the ability of robots to move accurately along defined paths is critical for their performance and effectiveness. In this article, we'll explore the importance of linear motion in robotics, how linear actuators and guides enhance robot performance, and present case studies showcasing the application of linear motion systems in various robotic contexts.

Understanding Linear Motion

Linear motion refers to the movement of an object along a straight line, where all points on the object travel in the same direction. This type of motion is one-dimensional, meaning it can be described using only one spatial dimension. Linear motion can be classifies as either uniform or non-uniform. In uniform linear motion, the object moves at a constant speed, while in non-linear motion, the object's speed varies over time. The ability to move in a straight line with precision is crucial in many robotic applications, enabling tasks to be performed with high accuracy and efficiency.

Linear Motion as the Backbone of Modern Robotics

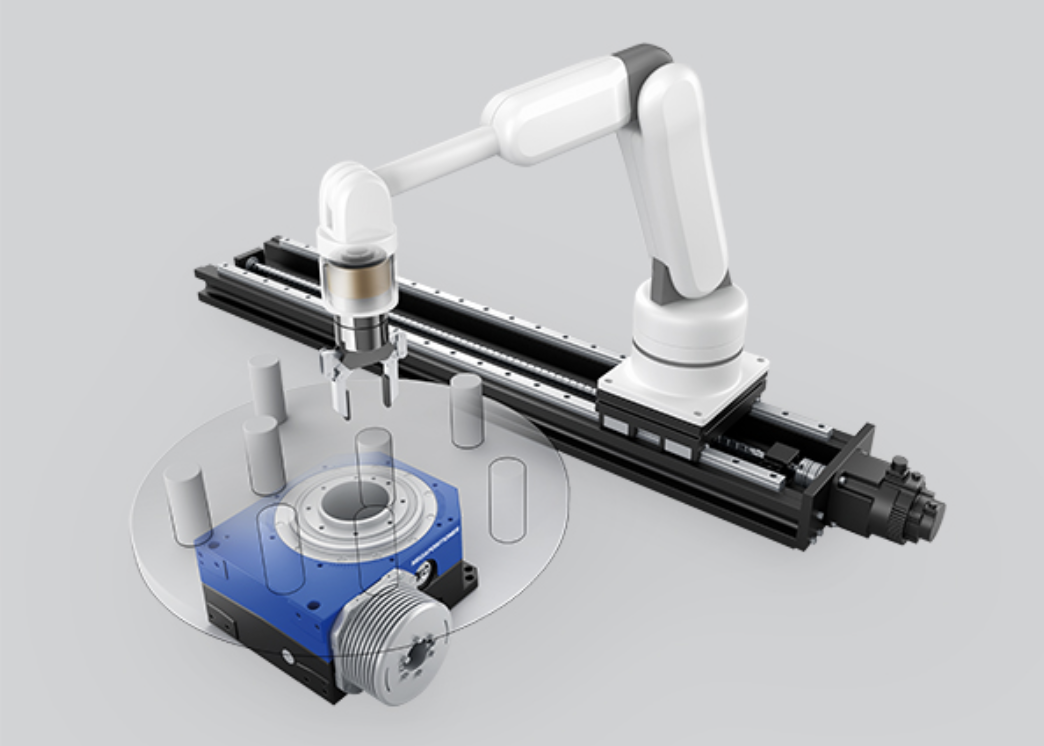

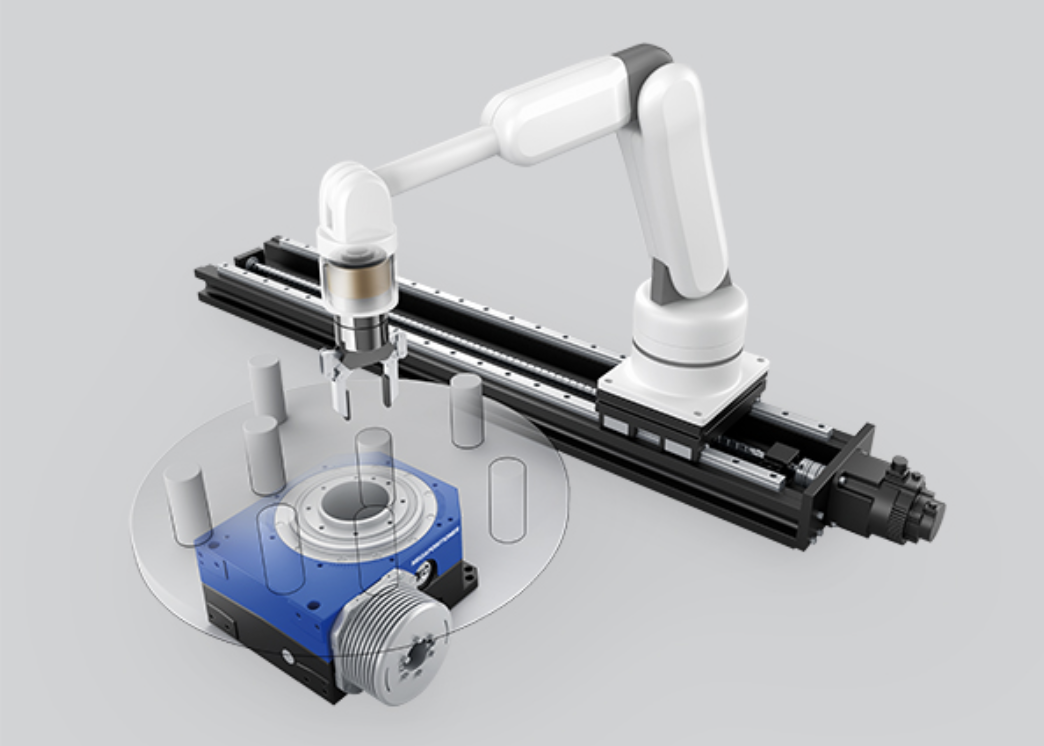

When we think about robotics, we often imagine machines that move in a systematic manner in all directions. However, linear robots, which operate solely in straight lines, are gaining traction in specific applications due to their distinctive advantages. These robots typically feature two or three principal axes that function at right angles to each other. This structure makes linear robots particularly suitable for repetitive tasks, providing high levels of accuracy and consistency.

One of the standout features of linear robots is the repeatability. Because they lack rotating axes and are designed to move in a particular direction, their mechanical structure inherently limits unnecessary movements. This increased accuracy leads to higher quality products and more predictable production volumes. In industries where precision is key, such as electronics assembly or pharmaceuticals, linear robots excel in providing consistent and reliable outcomes.

In addition, linear motion systems are perfect for environments where parts are presented in a consistent and reliable manner. They perform exceptionally well in mundane tasks such as pick and place, sorting, packaging, palletising, and assembly. In these scenarios, linear robots don't need to reposition or recalibrate to locate parts, allowing them to maximise productivity efficiently.

Enhancing Robot Performance with Linear Motion Guides and Actuators

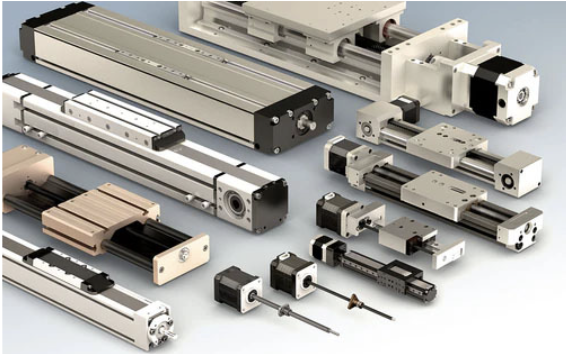

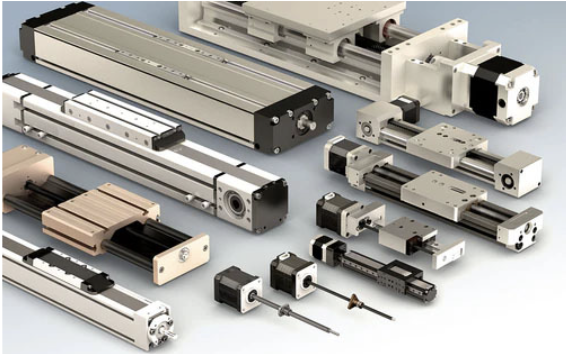

Linear actuators and guides play a vital role in enhancing robot performance. Linear actuators convert rotational motions to linear motion, allowing robots to achieve precise movement along a straight path. They can be three types: electric, pneumatic, or hydraulic, each with its own sets of advantages depending on the application requirements.

- Pneumatic Linear Actuators: Known for their cost- effectiveness, pneumatic actuators are widely used in industrial settings. They are quick in their movements are suitable for applications that involve lighter loads. Their simplicity and low maintenance requirements make them a popular choice in various robotic applications.

- Hydraulic Linear Actuators: Hydraulic linear actuators provide significant force and power, making them ideal for tasks requiring strength and stability, such as in industrial robots and material handling where heavy loads are involved.

- Electric Linear Actuators: These actuators are preferred for their precision and ease of control. They work perfectly for applications that require exact positioning and speed control. Their accuracy makes them suitable for tasks in automated manufacturing lines and robotics, where even the slightest error can lead to production issues.

In addition to actuators,

linear motion guides are essential for ensuring smooth and precise movement. These guides are typically made from hardened steel or aluminium, providing the necessary support and stability for the linear motion system. They reduce friction and enable efficient and reliable operation of the entire robotic system.

Key Benefits of Linear Motion Systems for Robotics

- Precision and Accuracy: They ensure that robots operate with exact measurements, which is crucial for tasks in sensitive industries like medical equipment manufacturing. Instantaneous velocity refers to the velocity of an object at a specific moment in time and is calculated through limits, being equivalent to average velocity when the velocity remains constant throughout the displacement.

- Efficiency and Speed: By minimising friction, linear motion systems allow for smooth and quick movements, enhancing the overall speed of operations, particularly in manufacturing and logistics. Instantaneous acceleration is a specific measure of how velocity changes at a particular moment in time and is represented on a velocity-time graph as the gradient at any specific point.

- Versatility: Linear motion systems are adaptable, finding applications across various sectors from manufacturing automation to medical devices. This versatility makes them a valuable tool in the ever-evolving landscape of robotics.

Learn more about SLS linear motion systems

here.

Applications of Linear Motion in Robotics

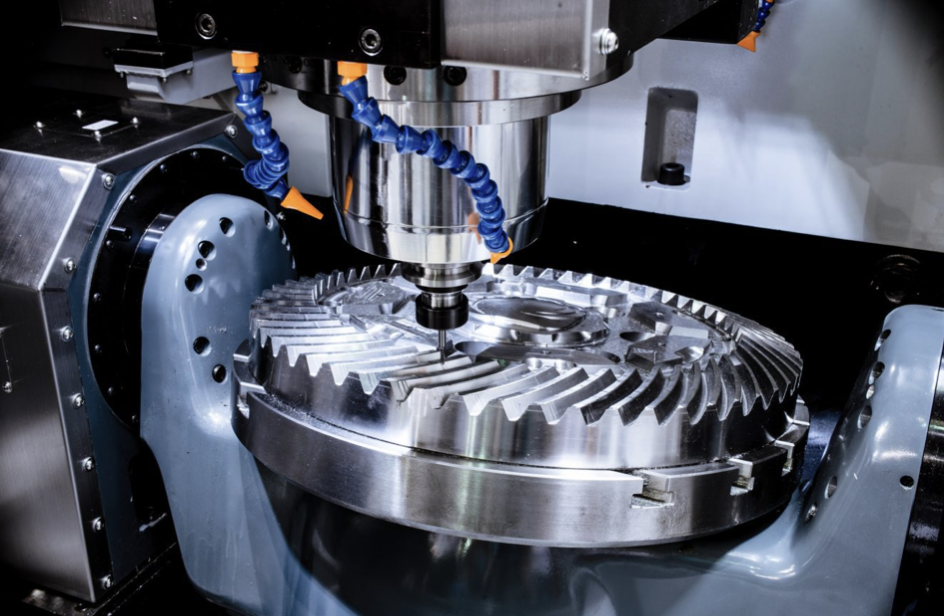

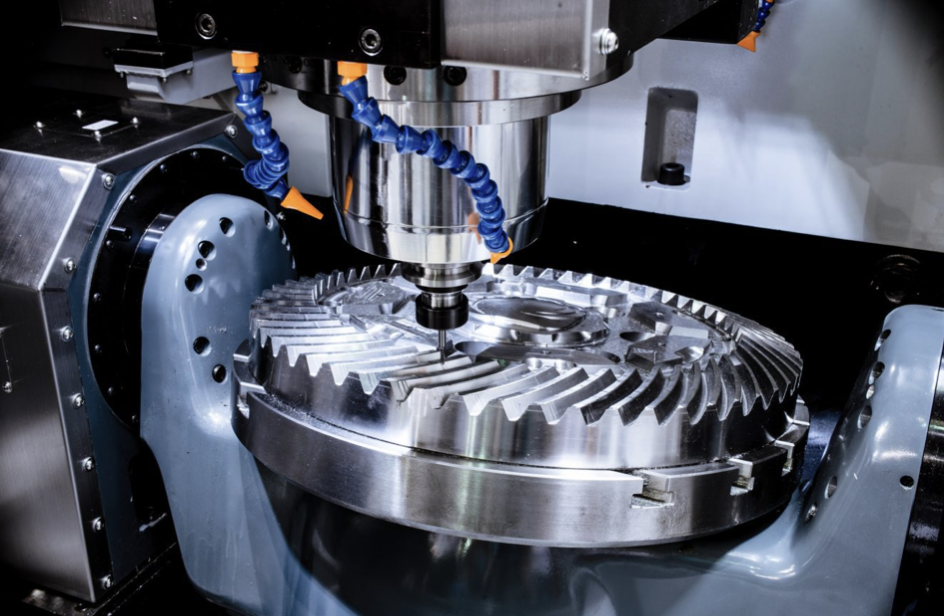

CNC (Computer Numerical Control)

CNC (Computer Numerical Control) machines rely heavily on linear motion systems to ensure precise cutting, drilling and shaping of materials. The use of ball screw systems in these machines convert rotational motion into linear movement, allowing for high accuracy in machining processes. By incorporating linear actuators, CNC machines can operate with tight tolerances, delivering high- quality products consistently. The gradient of a velocity- time graph represents acceleration at any given point, which is crucial for understanding motion over time in CNC operations.

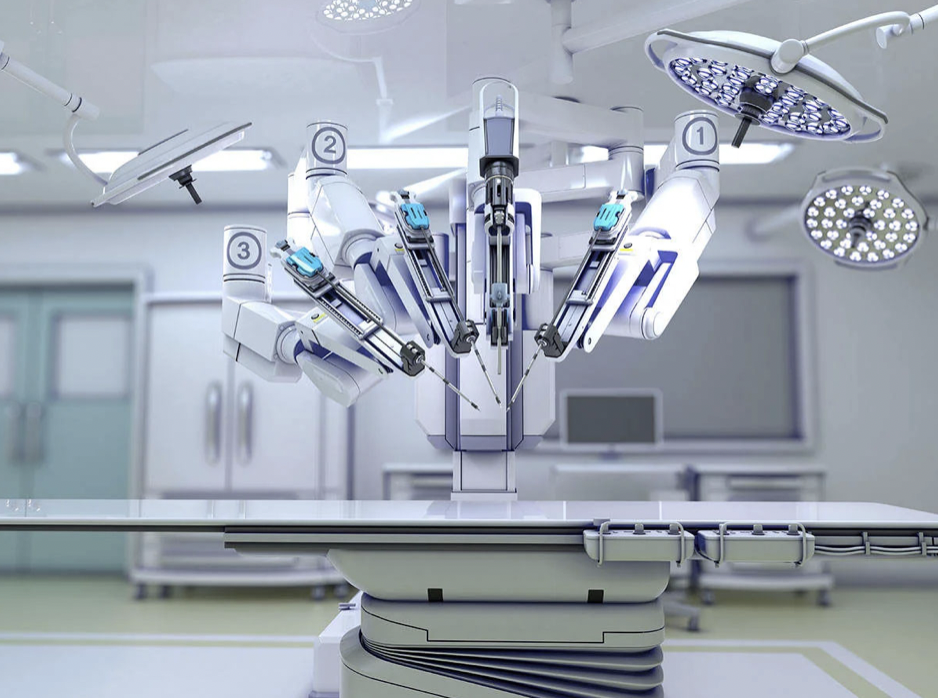

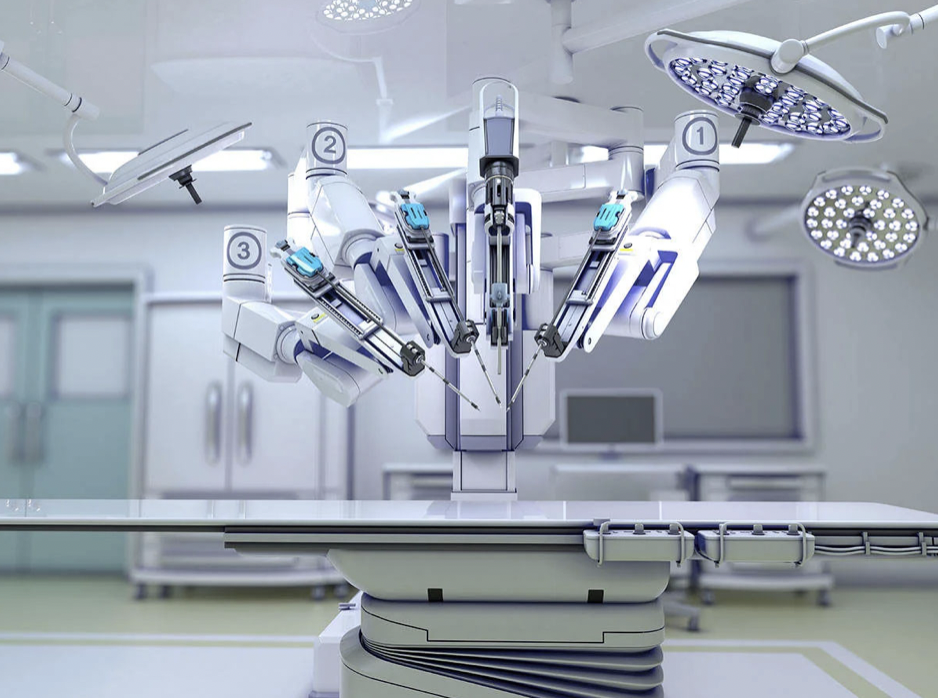

Robotics in Medical Equipment

Linear motion systems enhance the precision and accuracy of imaging divides such as MRI and CT scanners in the medical field. It ensures that imaging components move smoothly along predetermined paths, improving the quality of images produced. Furthermore, surgical robots benefit from linear motion, allowing for controlled and precise movements during minimally invasive procedures. The reliability and accuracy provided by linear motion systems are vital in maintaining patient safety and achieving optimal surgical outcomes. Analysing projectile motion helps in understanding the trajectories of surgical tools under gravitational acceleration, ensuring precise targeting and movement.

Conveyor Systems in Manufacturing

In manufacturing environments, linear motion systems are pivotal in conveyor systems that move products efficiently through production lines. These systems utilise belt- driven linear actuators that provide cost- effective and low maintenance solutions for transporting goods. By optimising the movement of products, manufactures can significantly reduce labour costs and enhance productivity, all while maintaining a high level of quality control.

Automated Storage and Retrieval Systems

Automated storage and retrieval systems are ideal in warehouses where the linear motion to quickly and accurately store and retrieve items. These systems rely on linear guides and actuators to navigate through aisles, retrieving products with minimal human intervention. By implementing linear motion systems, warehouses can optimise their storage capacity and improve overall efficiency, reducing downtime and operational costs.

Linear motion plays a crucial role in the efficiency and accuracy of robotic application across various industries. From the precision of CNC machines to the reliability of automated storage systems, the ability to move in straight lines is a key component of many robotic systems. By understanding the importance of linear motion, we can better appreciate how linear actuators and guides enhance robot performance.

As robotics continues to evolve, the demand for linear motion systems will likely grow. By leveraging these systems, industries can improve their productivity, quality, and competitiveness. Whether you're manufacturing, healthcare, or logistics, embracing linear motion in robotics is a step toward optimising your operations and staying ahead in an increasingly automated world.

For those seeking professional assistance or specialised expertise in dealing with linear motion in robotics, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our extensive

reduction gears and actuators for robotics on our website.

Get in touch with us for professional help and greater operational efficiently today!

Contact Us

Contact Us