Products & Services Industry Guides

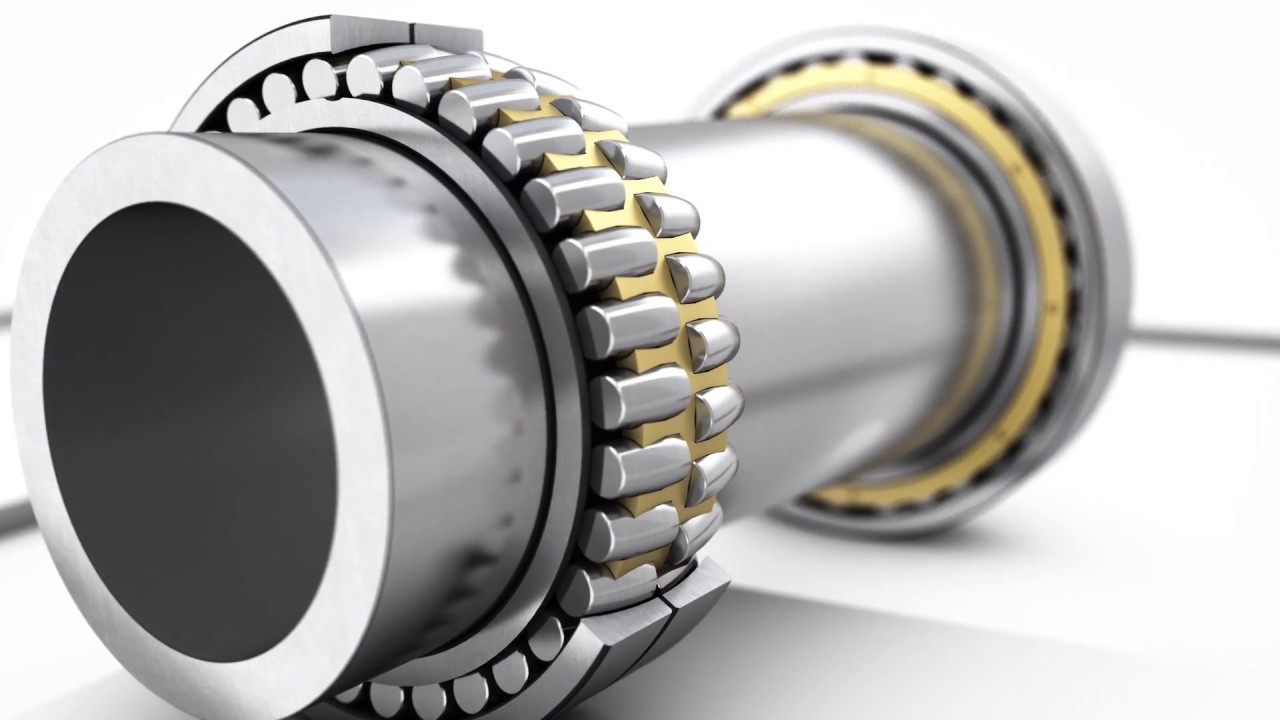

Spherical roller bearings are bearings that permit rotation with low friction and angular misalignment. This is made possible due to its spherical internal shape, accompanied by the spherical rollers.

This article will explore the overview of spherical roller bearings, highlighting their design and capabilities such as built-for tolerances, enabling smooth operation under heavy loads and the bearings' features.

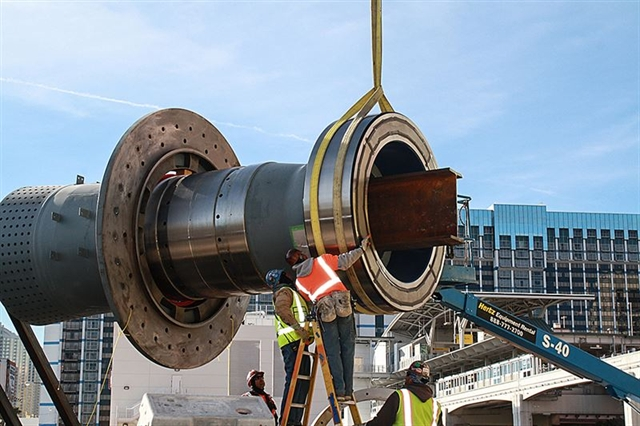

Spherical roller bearings are essential components in machinery and industrial equipment, renowned for their versatility and capability to withstand heavy radial and axial loads.

With a unique design that allows for angular misalignment and accommodates shaft deflections, these bearings ensure smooth operation and extended service life in diverse applications across various industries.

According to Oxford academics, spherical roller bearings are also sometimes referred to as 'barrel roller bearings' as their rolling elements are normally barrel-shaped.

What sets spherical roller bearings apart is their spherical-shaped roller elements, which are meticulously crafted to ensure optimal load distribution across the bearing surfaces.

This innovative design not only enhances load-carrying capacity but also enables the bearings to withstand higher loads compared to traditional cylindrical or ball bearings.

Spherical roller bearings are engineered to excel in demanding industrial environments, offering unparalleled performance and reliability.

Among their many notable features, their exceptional capability to withstand heavy loads stands out as a testament to their robust design and superior engineering.

Several key designs that contribute to this capability include:

Material Selection: High-quality materials, such as premium-grade steel alloys, are used in the manufacturing of spherical roller bearings to ensure exceptional strength, durability, and resistance to fatigue under heavy loads. These materials undergo rigorous heat treatment and surface finishing processes to enhance their mechanical properties and performance characteristics.

Optimised Internal Geometry: The internal geometry of spherical roller bearings is carefully optimised to enhance load-carrying capacity and reduce stress concentrations. This includes precision-engineered raceway profiles and roller geometries that minimise friction and wear while maximising the bearing's load-handling capabilities.

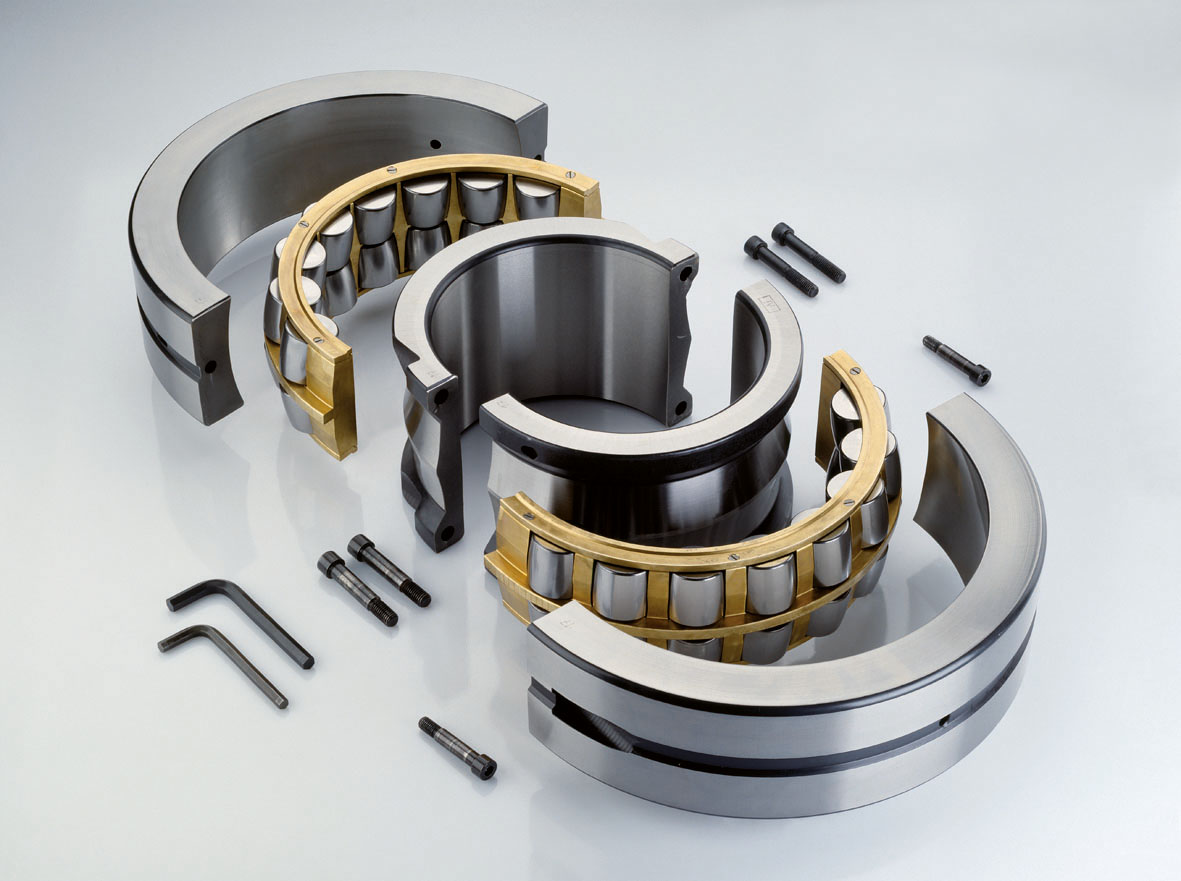

Spherical Shaped Rollers: Unlike traditional cylindrical rollers, spherical roller bearings feature barrel-shaped rollers that distribute loads more evenly across their surfaces. This design allows for a larger contact area between the rollers and the raceways, enabling the bearings to handle higher loads without experiencing excessive stress concentrations.

Spherical roller bearings are meticulously engineered with several design features that make them well-suited for tolerances, including:

Symmetrical Roller Profile: The symmetrical design of spherical rollers ensures uniform load distribution and balanced contact stresses across the bearing surfaces. This feature helps maintain precise tolerances by minimising deformation.

Robust Cage Design: Advanced cage materials and designs are employed in spherical roller bearings to ensure dimensional stability. It also provides resistance to deformation, maintaining precise tolerances even under heavy loads and high-speed operation.

Although bearings are well-suited for tolerances due to their precision engineering, regular machine inspections by professionals are also things to be taken into account to ensure their longevity.

Spherical bearings offer greater benefits to their counterparts since it is unique in terms of resistance, design and build quality.

Here are other various features which also contribute to its efficiency and optimal performance:

Continuous Alignment: Spherical roller bearings retain their alignment throughout their entire lifespan. In contrast to tapered roller bearings that require realignment after each use, spherical roller bearings can operate continuously without the need for maintenance.

Self-Aligning Capability: Throughout their operation, spherical roller bearings can self-align. No special equipment is required as the bearings are designed in such a way to maintain the inner race to be perfectly centred on the outer race.

In conclusion, gaining knowledge about spherical roller bearings is crucial for professionals and enthusiasts alike in various industries.

Understanding their design and capabilities not only enhances technical expertise but also ensures optimal performance and reliability in machinery and equipment.

For those seeking professional assistance or specialised expertise in dealing with spherical roller bearings, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services, including consultation, installation, and maintenance, and provide tailored solutions to meet the unique needs of clients across various industries

You can also browse our extensive spherical roller bearings selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Precision-engineered linear bearings solutions for smooth operation and optimal performance.

Find Out MorePrecision-engineered linear bearings solutions for smooth operation and optimal performance.

Find Out More

Contact Us

Contact Us