In today's industrial landscape, it's hard to imagine processes processes running smoothly without the magic of pneumatics. Pneumatic grippers are the unsung heroes of automation, seamlessly handling a variety of tasks across multiple sectors. From automotive assembly lines to food packaging facilities and electronics manufacturing, these versatile tools play a crucial role in ensuring efficiency, safety, and productivity. In this blog, we'll delve into the fascinating world of pneumatic grippers, highlighting their applications in the automotive industry, food and beverage sector, and electronics manufacturing.

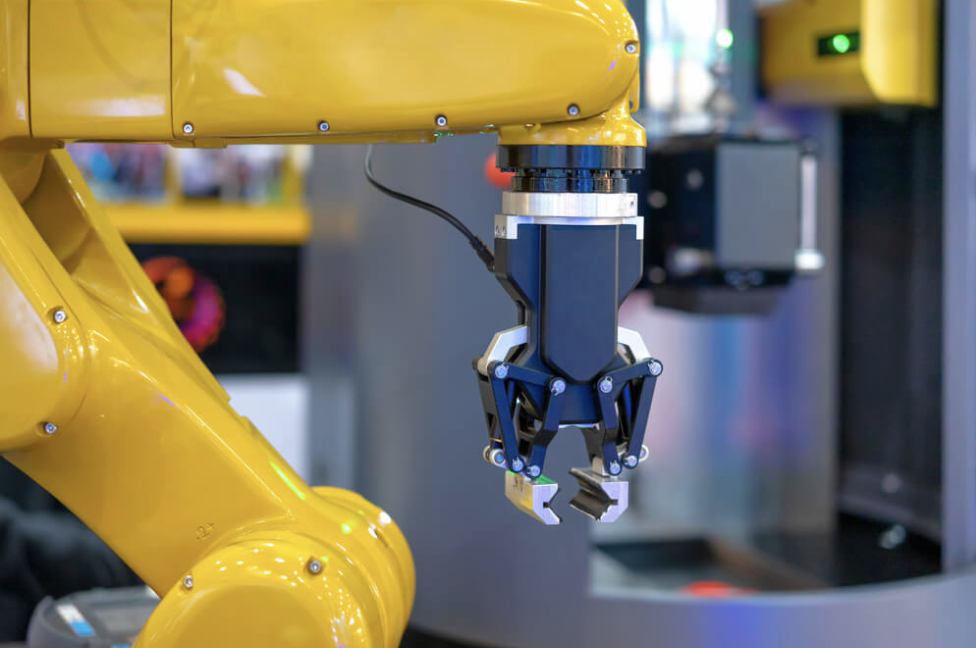

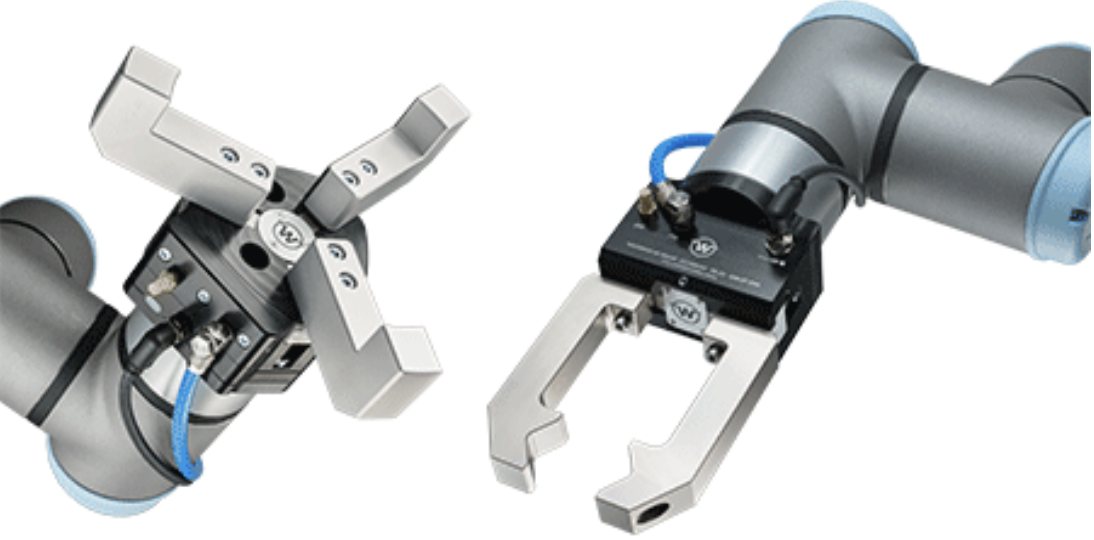

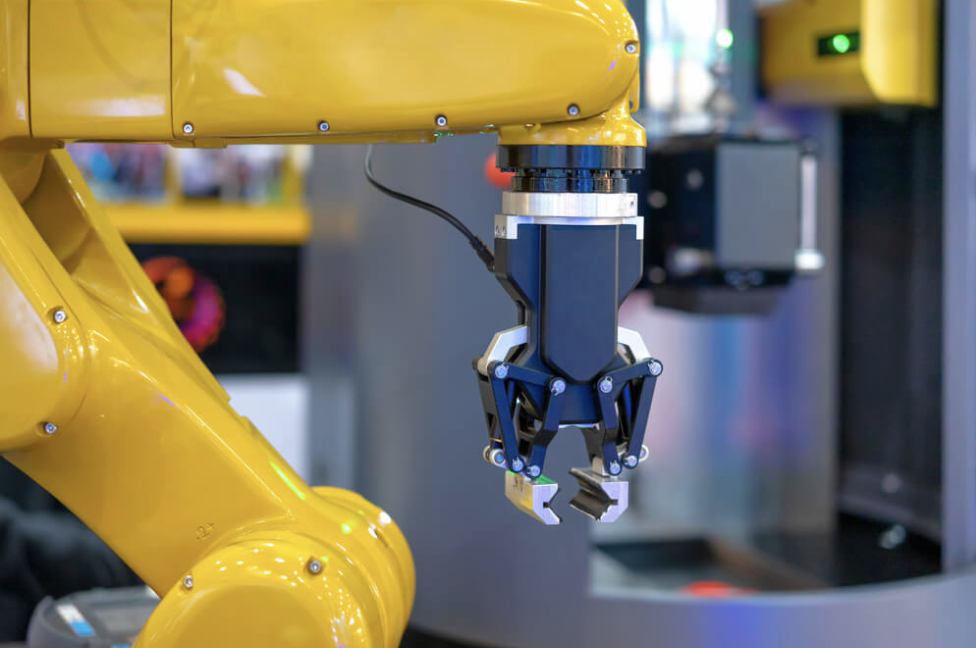

Pneumatic grippers are a type of pick-and-place device that use compressed air to operate. The use of compressed air allows for precise and controlled movements, enhancing the functionality and precision of pneumatic grippers. Integrated control technologies allow for the monitoring of gripping positions, improving the effectiveness of the grippers in automated manufacturing processes by utilising sensors and advanced pneumatic technology.

The Role of Pneumatic Grippers

Pneumatic grippers have long been the go-to solution in automation, known for their durability, maintenance-free operation, and robustness across various environments. Most grippers in use today operate pneumatically, thanks to their ability to deliver reliable performance for tasks involving components of all shapes and sizes. Air ports facilitate manifold mounting by directing air lines away from the gripper area, ensuring efficient operation and proper airflow for the device. This reliability is particularly vital as it directly influences the overall efficiency and safety of industrial processes.

The latest advancements in pneumatic gripper technology have introduced options that boast certified safe gripping force maintenance and integrated sensor systems. These advanced grippers open the door to new possibilities, making them ideal choices for industries requiring precise and efficient handling.

Automotive Industry

High Speed Automation

Automating tasks such as assembly, painting, and material handling are done by pneumatic grippers in the automotive industry. The speed and reliability of pneumatic systems make them ideal for high-speed pick-and-place applications. Pneumatic grippers provide fast and secure gripping of components, increasing their efficiency and allowing manufacturers to meet the increasing demand for vehicles.

Robust Handling

Pneumatic grippers can withstand the dirt and debris which are common in automotive manufacturing. They have the ability to operate in harsh conditions and handle everything from lightweight plastic parts to heavy metal components, ensuring that assembly lines run smoothly without interruption.

Adaptability

Moreover, the integration of advanced sensor technology enables real-time diagnostics, enhancing process monitoring and individualisation. This allows automotive manufacturers to swiftly adapt to changing production needs and increase overall efficiency. The versatility of pneumatic grippers in handling various workpieces make them a staple in the automotive sector.

Food and Beverage Industry

Hygiene Compliance

With demands of high levels of hygiene and precision in the food and beverage industry, pneumatic vaccum grippers are a perfect fit for this sector. These grippers can handle packaging sorting, and palletising tasks while maintaining the stringent cleanliness standards required in food processing.

Secure Gripping

Advanced pneumatic grippers are particularly suited for food and beverage applications due to their certified gripping force maintenance, ensuring that products remain securely held during handling. This safety feature prevents the accidental release of items, which could lead to contamination or loss of product integrity. With a robust design that can handle the challenges of moist environments, pneumatic grippers perform exceptionally well in food and beverage facilities.

Easy Integration

In addition to their reliability, pneumatic grippers are lightweight and easy to commission, enabling food manufactures to implement automation quickly and efficiently. The ability to switch between different operational modes further enhances the flexibility of pneumatic grippers, allowing users to adapt them to different production requirements seamlessly.

Electronics Manufacturing

Precision Handling

The electronic manufacturing sector is another area where pneumatic grippers are an essential. With the increasing demand for small, intricate components, these grippers excel at handling delicate items with precision and speed.

Technological Advancements

The efficiency in operations is paramount in electronics manufacturing. Pneumatic grippers help reduce cycle times, ensuring that components are moved swiftly and safely throughout the production process. Their compact size allows for the integration of multiple grippers within a single automation cell, maximising output and productivity.

Compact Design

An invaluable asset to the electronics manufacturing industry is the ability of pneumatic grippers to distinguish between workpieces is invaluable in electronics assembly, where variations in parts can impact performance. Integration sensor systems can monitor the position of fingers throughout the gripping process, allowing for precise handling of various components and reducing the risk of errors.

Future of Pneumatic Grippers

As industries evolve, so do pneumatic grippers. With ongoing advancements in technology such as the integration of digital features and enhanced safety mechanisms, pneumatic grippers are set to remain at the forefront of automation. The ability to collect and analyse data in real-time opens up new possibilities for process optimisation and efficiency gains across all sectors.

For instance, manufacturers can offer a wide range of options for users, allowing them to customise pneumatic grippers according to their specific needs. Their flexibility and adaptability make them valuable tools in various applications, ensuring that manufacturers can keep with changing demands and maintain a competitive edge.

In the food and beverage industry, continued innovations in pneumatic grippers will likely lead to even greater levels of hygiene safety. As the focus on health and food safety increases, pneumatic grippers will play an integral role in ensuring that products are handled with care and meet regulatory requirements.

The automotive industry will also benefit from advancements in pneumatic gripper technology enabling faster assembly times and enhanced safety features. As manufacturers strive to improve production efficiency, the role of pneumatic grippers will becomes even more critical.

Pneumatic grippers have proven to be indispensables tools across various industries, including automotive, food and beverage, and electronics manufacturing. The reliability, efficiency, and adaptability make them ideal for handling a wide range of components and products. With advancement in technology, pneumatic grippers are not only meeting the current demands of the industrial landscape but are also poised to drive future innovations in automation.

For those seeking professional assistance or specialised expertise in dealing with pneumatic grippers, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our extensive

pneumatic gripper selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Contact Us

Contact Us