Products & Services Industry Guides

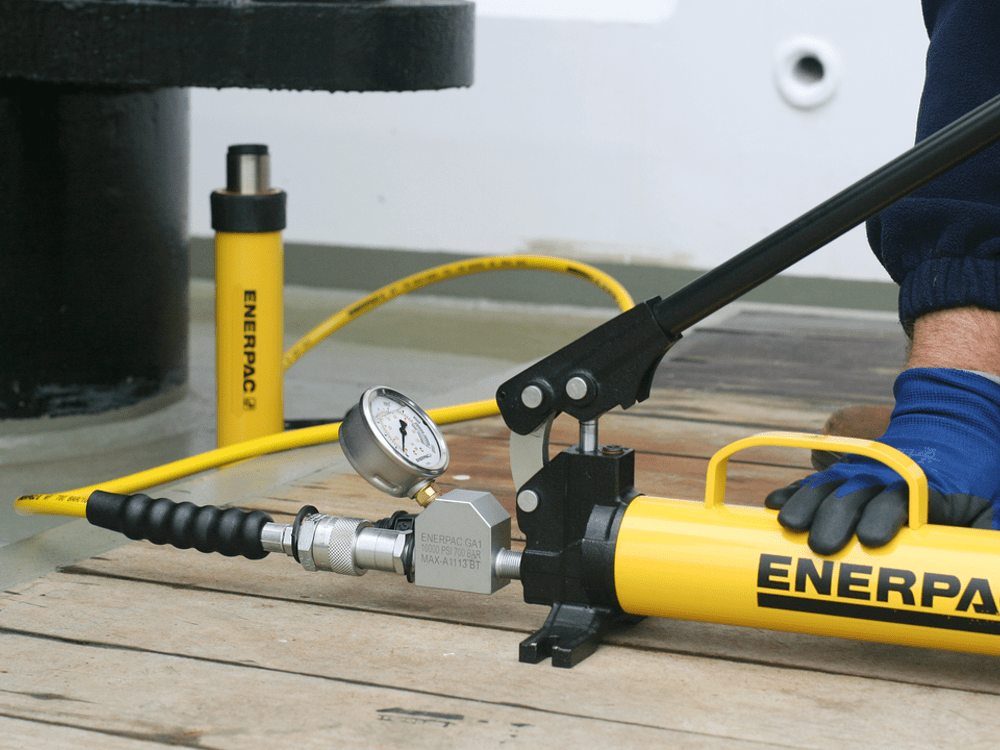

A hydraulic jack is a hydraulically powered jacking device that operates by the liquid supply and provides hydrostatic pressure through its pump and reservoir.

The two common types of hydraulic jack are hydraulic floor jack and bottle jack, which have their respective strength in lifting either vertical or horizontal load, depending on height and usage requirement.

Throughout history, the hydraulic jack has continually evolved, building upon the knowledge of previous advancements.

The hydraulic jack was first invented in 1851 by Richard Dudgeon, and it was referred to as a "portable hydraulic press" back then.

During this time, Richard got his invention patented and continued developing his linear lifting jack, making a significant improvement to the hydraulic industry.

Hydraulic jacks operate based on Pascal's principle, which is built on the idea that when pressure is applied to a confined, incompressible fluid, it will be equally distributed in all directions.

When a hydraulic pump operates, this incompressible fluid will be driven to a smaller volume by mechanical energy and the pressure in the fluid will increase.

According to Physlink.com, the pressure is calculated by the method of Force equal to Pressure multiplied by Area, F= PA. So, when the high-pressure fluid is transmitted from a smaller volume (smaller cylinder) to a larger volume (larger cylinder), the pressure remains constant.

However, a greater force is generated since the larger cylinder has more area.

Preparatory works are crucial before using a hydraulic jack, otherwise, your equipment will not work as efficiently.

Here are the following preparation tips that can be done before operating your jack:

Checking Fluid Levels: Ensure that the hydraulic fluid reservoir is filled to the recommended level with the appropriate type of hydraulic fluid. Check for any contaminants or impurities in the fluid and address them accordingly. Top up the fluid if necessary, following manufacturer recommendations.

Understanding Load Requirement: Calculate the maximum load the hydraulic pump needs to handle in your application and consider additional factors that may affect the load weight such as friction and dynamic loads.

Inspect Equipment: Before using the hydraulic pump, thoroughly inspect all components. You can look for signs of damage or leaks that may affect performance before operating the equipment.

Review Operating Procedures: Review the manufacturer's operating manual and guidelines for the specific hydraulic pump model being used and familiarise yourself with it.

Emergency Preparedness: Establish emergency procedures and protocols in case of accidents, malfunctions, or other unexpected events during hydraulic pump operation

Using the hydraulic jack safely is imperative as it can easily cause accidents and injuries because of negligence.

Here are some best practices you can follow when using them:

Type of Hydraulic Jack: In case multiple jacks are used to lift the same equipment, the same type of hydraulic jack should be used during the applications.

Cleaning up the Hydraulic Jack: Clean the hydraulic jack before using it and check each component to ensure no damage has occurred.

Test Safety Features: Familiarize yourself with the safety features of the hydraulic pump, and test these features to ensure they are functioning correctly and can be activated if needed during operation.

When using hydraulic pumps, several safety standards need to be implemented to ensure safe and efficient operation, such as:

The base area of a hydraulic jack serves as the foundation for lifting heavy loads. A solid and level support surface is essential for maintaining stability and preventing the jack from tipping or shifting during operation.

In addition, it promotes efficient load distribution as a solid support surface helps distribute the weight of the load evenly across the base area of the hydraulic jack. This prevents excessive stress or pressure on specific areas of the jack, reducing the risk of damage or failure during lifting operations.

Solid support ensures stability and prevents the hydraulic jack from sinking or shifting during lifting operations, and avoid placing any body parts under the hydraulic jack without ensuring the load is on a solid support or cribbing. Examples of solid support include:

Concrete Surface: Placing the hydraulic jack on a level concrete surface provides a solid foundation for lifting operations.

Steel Plates or Platforms: Using steel plates or platforms under the base area of the hydraulic jack can provide additional stability and support, especially on soft or uneven surfaces.

Wooden Blocking: Wooden blocking or cribbing can be used to create a solid and level support surface for the hydraulic jack. Wooden blocks or planks are stacked securely under the base area of the jack to provide stable support on uneven or irregular surfaces.

Jack saddle has to be in contact with the load to ensure the stability and integrity of the lifting operation.

It helps by providing a proper placement to distribute the load evenly and should be centred and aligned with the designated lift points or support areas of the load to prevent tipping or shifting during lifting.

The contact area between the jack saddle and the load should also be sufficient to prevent excessive pressure on specific points as it helps minimize the risk of damage to the load.

In conclusion, the importance of practising safety guidelines when using hydraulic jacks cannot be overstated.

Following these guidelines helps prevent a range of accidents, injuries, and damage to the equipment or surrounding environment.

If you're unsure of which type of hydraulic jack is best for your operation, consult our team of experts in SLSPRO.

You can also browse our extensive selection of hydraulic jack products on our website.

Get in touch with us for professional help and greater operational efficiency!

High-quality industrial tools for efficient and reliable performance in construction, manufacturing, automotive, aerospace, and more.

Find Out MoreHigh-quality industrial tools for efficient and reliable performance in construction, manufacturing, automotive, aerospace, and more.

Find Out More

Contact Us

Contact Us