Products & Services Industry Guides

.webp)

In an industry that has been ever-increasing its reliance on automation, plants and facilities need to realise the significance that predictive maintenance plays in the balancing of its books and employ the necessary measures to maintain these machines with increased priority.

In the context of linear motion technology, the maintenance of linear bearings , like all bearings, require proper and timely lubrication to minimise unscheduled downtime.

to invest in your linear bearing maintenance can yield higher returns in the long run.

To help, we compiled the 4 most common mistakes and how to build proper maintenance procedures for your linear bearings.

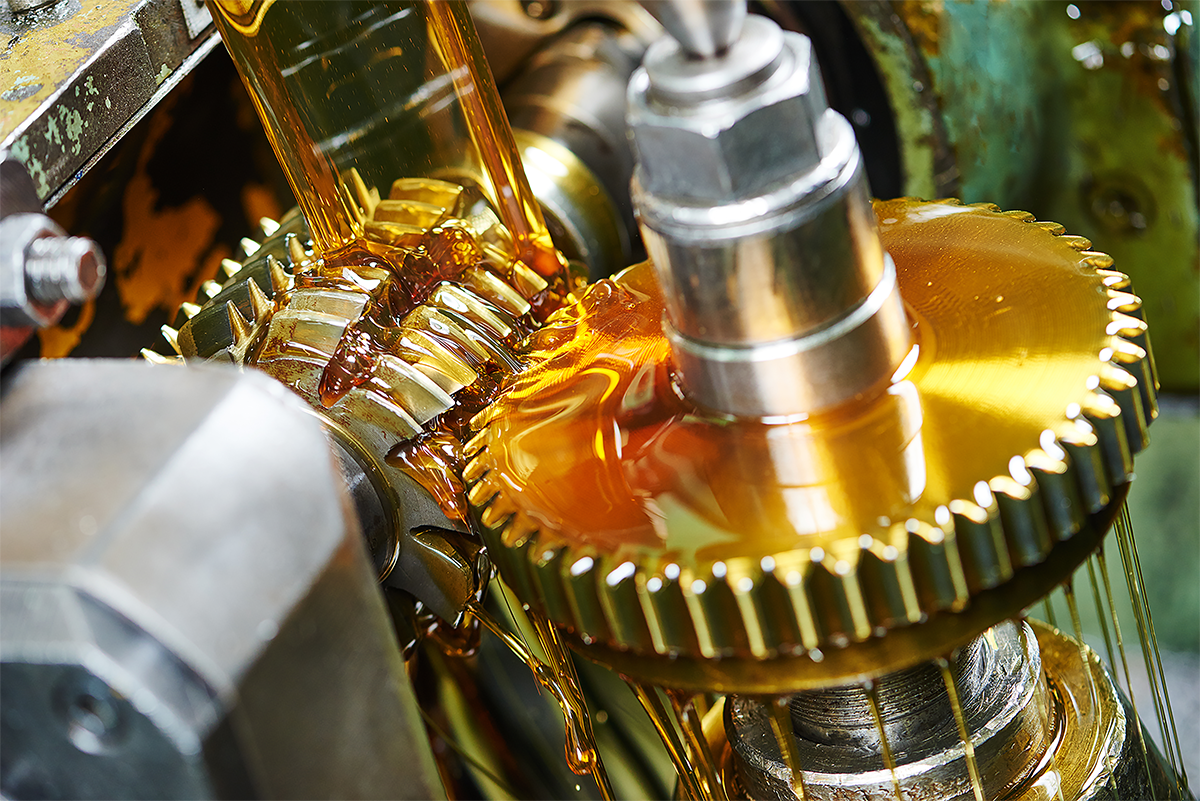

Inadequate or improper lubrication is actually one of the leading causes of linear motion technology failures. Lubricating your linear bearings is essential in prolonging its lifespan and performance which would significantly affect your facility's output.

An age-old process, lubrication minimises friction and prevents wear & tear of machines. It also protects against corrosion and contaminants. Under-lubricating your linear bearings can generate heat from the friction between the moving parts.

The common practice is to perform preventive maintenance at weekly or monthly periods. With automatic lubricators, this process can be regulated to reduce your work. It is typically used for systems that are difficult to access. However that often isn't enough and could potentially set you up for bearing failure down the road.

Instead, a strategic combination of both is recommended. At SLS Bearings, we advocate for predictive maintenance where lubrication is scheduled as needed. We advise against only lubricating your linear bearings when the schedule is up. Proper monitoring and measurement of friction levels should be conducted with ultrasound instruments periodically to gather data that informs the most accurate linear bearing in conditions.

Grease flowing into the bearing cavity fills it up eventually. If relief ports are absent, the seals will be blown through and leak out of the housing. This causes an issue where an opportunity for external contamination can happen.

Excessive grease builds up pressure between the rolling elements and the outer race, resulting in more force needed for the bearing to push. Too much grease also causes heat from fluid friction. Unlike oil, grease doesn't transfer heat out. As the temperature builds, the grease degrades from over-churning. With relief points to remove excess grease, over-lubricating your linear bearings is a less concerning issue when compared with under-lubrication.

Selecting the appropriate lubrication for linear bearings is important to ensure optimal performance, longevity, and reliability of machinery.

One prevalent mistake is underestimating the operational conditions and demands of the application. Failing to consider factors such as load capacity, speed, temperature variations, and environmental conditions can result in lubricants that are either too viscous or too thin, leading to insufficient protection or excess friction and wear on bearings.

Another critical error is neglecting compatibility issues between the lubricant and the bearing materials. Certain lubricants may contain additives or chemicals that can degrade or corrode specific bearing materials, leading to premature failure and costly downtime. Lubricants with inadequate longevity or stability might require frequent reapplications, increasing maintenance costs and the risk of human error.

Furthermore, cost-driven decisions can lead to subpar lubrication choices. Opting for cheaper alternatives without considering their performance characteristics can compromise the efficiency and overall lifespan of the linear bearing, ultimately costing more in repairs and replacements.

For most applications, the grease has to be re-applied at scheduled intervals as the "old" grease dries out and oxidises. After re-greasing, this "old" contaminated grease will be pushed out of the bearing housings.

Planning a comprehensive maintenance schedule for your linear bearings isn't the easiest task as the proper amount of lubrication to apply is tough to predict precisely. The variables include the size & speed of the linear bearing, its operating temperature and operation hours.

Some systems require weekly or monthly lubrication while others on a daily basis. It is recommended to do a complete wash out of your bearings at least once yearly and apply a brand new coat of grease. Before you dispose of the "old" grease, make sure to send it to the lab for analysis. The analytical data is your best bet when it comes to fine-tuning the efficacy of your greasing schedules.

As mentioned earlier, bearing life heavily depends on proper and timely maintenance. In fact, it is estimated that up to 80% of bearing failures result from lubrication-related issues.

While the number sounds high, it is not a difficult process. Many firms suffer from poor standard operating procedures (SOPs) and lack of strategic maintenance schedules.

To start, clean off any leftover grease, corrosion protection coatings and oils. This is a critical step in preserving its operating life while also preventing unwanted contaminants.

Note: Products that come pre-coated might not require this step. This is provided the coating has a micro-thickness and suitable with your lubricants.

For best practices, we recommend using cleaning solvents that do not leave any residues. Stock up on Permatex degreasers in our e-shop.

Pay special attention to this step as it often contributes to over- or under-lubricating your linear bearing. Your lubricant fill quantity's is to provide the contact surfaces between metals with consistent lubrication.

Applying too much lubricant causes increased heat generation and friction in your bearing housings. Applying too little means not all of the contact surfaces are evenly lubricated and leads to wear & tear and shorter operating life.

When proper fill quantities are achieved, the contact surfaces of bearings should have sufficient lubricating fillms. The correct quantity is determined on a case-by-case basis where we will elaborate in the next step.

Using industrial standards, proper fill quantities of lubricated bearings are defined as the percentage of the bearing's free space.

You can easily get this information with a simple phone call/email to your bearing manufacturer or using a grease calculator. However, note that the latter has limited accuracy.

During the run-in process, your linear bearing elements are filled with grease to form a grease collar. This method provides even distribution of the base oil where friction surfaces get optimal oil quantity.

Purge leftover grease found in your system.

Create a grease collar to deliver oil to the surface contact zone.

Let the the system cool down to room temperature.

Restart the procedure at the last speed prior to temperature spike.

Continue the above cycle till maximum operating speed is achieved.

Lubricate your linear bearing in a dry & clean environment to minimise any contamination from moisture or debris. Make sure to use a grease gun that's been calibrated or a syringe for smaller amounts. The bearings should then be rotated without load, to distribute the grease evenly through the race.

Proper maintenance of linear bearings is crucial to ensure optimal performance, longevity, and cost-effectiveness in industrial settings.

Find the most suitable bearing lubricant for your application in our SLS e-shop.

If you're looking to replace your bearings, check our out product offerings under Samick & Ewelix

The four common maintenance mistakes to avoid, including under-lubrication, over-lubrication, wrong lubrication choice, and insufficient maintenance. It is important for plants to plan for strategic & predictive maintenance practices, such as monitoring friction levels and conducting regular analyses of lubricants.

By following the provided maintenance tips, including pre-cleaning, proper fill quantities, calculation of bearing free space, and run-in procedures, industries can significantly reduce the risk of bearing failures and unscheduled downtime.

Ultimately, investing in linear bearing maintenance will yield higher returns in the long run and lead to improved facility output and productivity.

Precision-engineered linear bearings solutions for smooth operation and optimal performance.

Find Out MorePrecision-engineered linear bearings solutions for smooth operation and optimal performance.

Find Out More

Contact Us

Contact Us