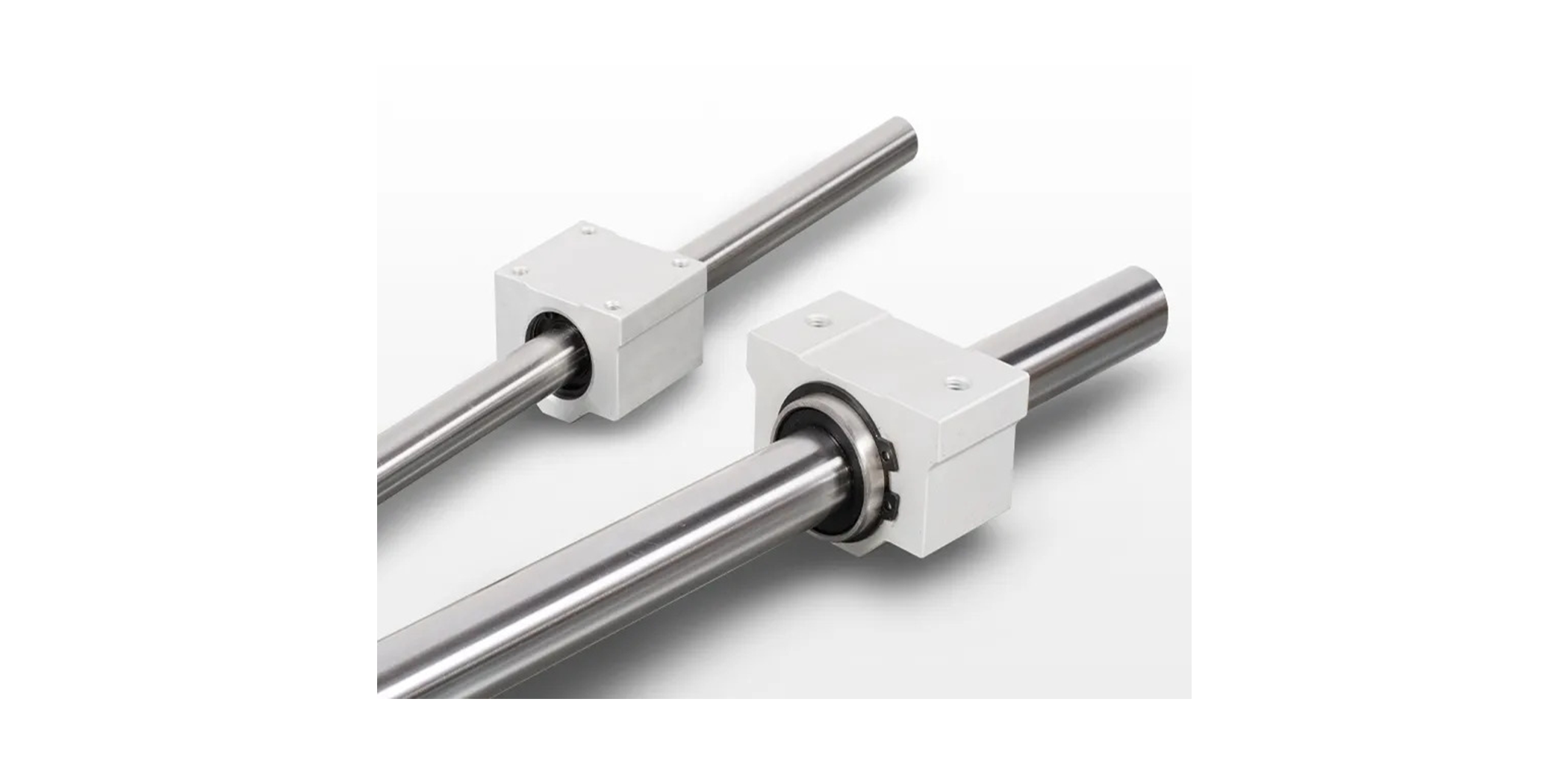

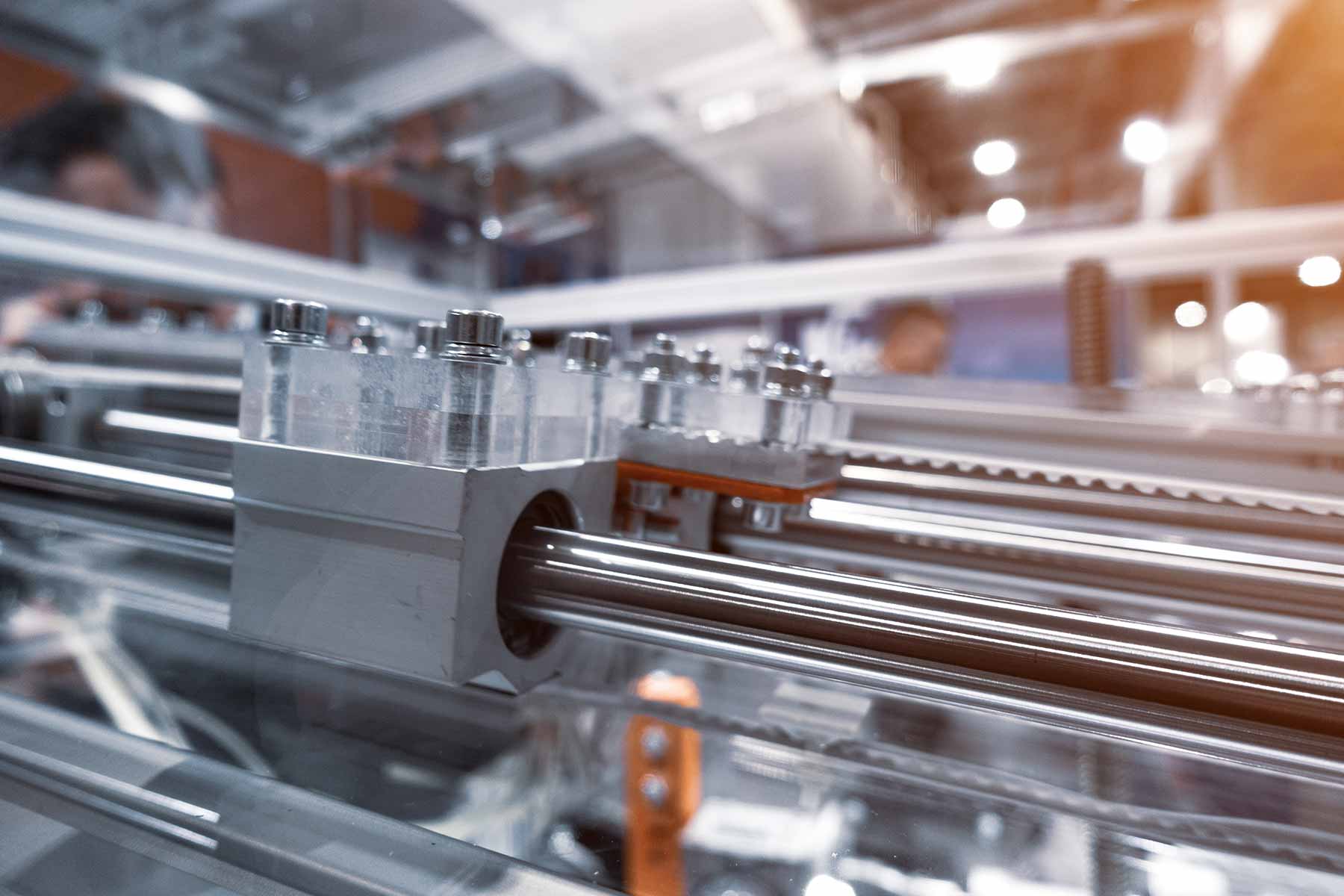

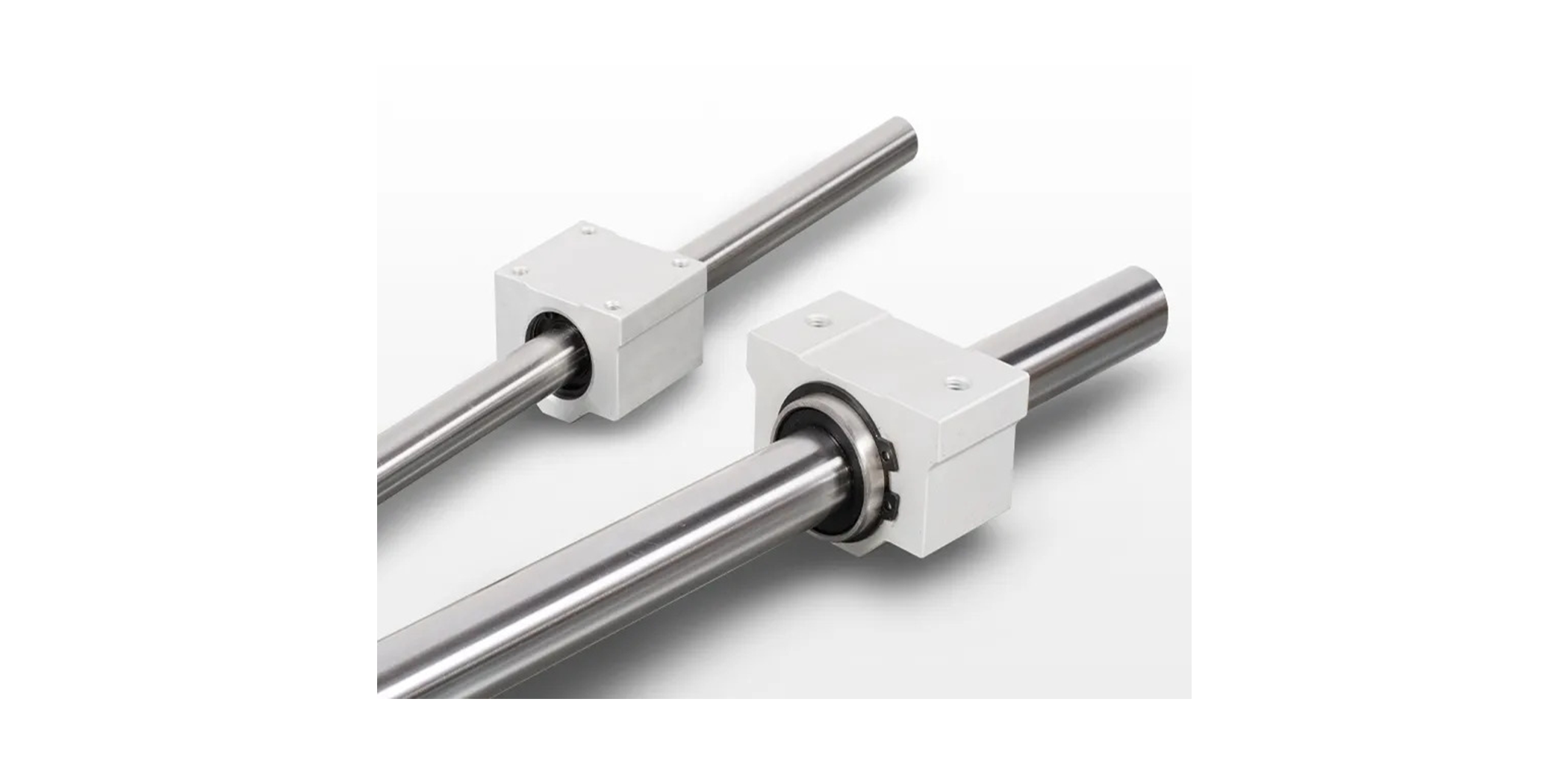

The linear guide shaft is an integral part of the linear motion system, being the main guide for the bearing. There are several factors of importance to take into consideration in order to ensure both smooth motion as well as the longevity of the linear guides.

This article aims to provide guidance on the qualities of linear guide shafts to understand what improvement you need for your linear guides to improve your linear motion systems.

1. Shaft Material Selection

Different materials are used in the development of liner guide shafts. This is due to the different applications for different industries, thus a range of metals to produce shafts are required to achieve the optimal end solution for your linear motion.

These are some of the material types for linear guide shafts:

- Stainless Steel:

- Corrosion Resistance: ability to function in harsh conditions such as environmental humidity or with chemicals

- Reliability: Strong, reliable and durable

- Lowered Costs: Requires little maintenance, reducing downtime and operating costs

- Commonly used in: Automotive, food processing and medical equipment

- Carbon Steel:

- Reliability: Robust, strong and durable

- Reduced Weight: increased efficiency, manoeuvrability, and lower energy cost

- Precision: When paired with a linear ball bushing, it offers smooth and accurate linear motion

- Hollow Design: different gases, fluids, or electrical wires can travel through the centre

- Commonly used in: Industrial, food processing and medical equipment

- Aluminium:

- Corrosion Resistance: resistance to oxidation avoids the need for regular maintenance or replacement

- Conductivity: good electrical and thermal conductivity

- Reduced Weight: increased versatility, non-magnetic, and lightweight

- Commonly used in: Construction, medical, oil and gas mechanisms

2. Shaft Surface Finishes

2.1 Coating

Coatings provide protection in order to help improve durability of the linear guide shaft. There are a variety of materials used in coating the shaft.

These are some of the coating types for linear guide shafts:- Black Oxide: prevents corrosion resistance and light reflection and additionally does not result in peeling

- Black or Clear Anodise: additional resistance to corrosion and wear

- Electroless Nickel: improves resistance to corrosion and wear for aluminium through extra hardening

- Ceramic: improves resistance to corrosion and wear when used on aluminium

- Hard Chrome: improves resistance to wear and abrasion for steel

- Low-Temperature Black Chrome: corrosion resistance and achieves high precision tolerance

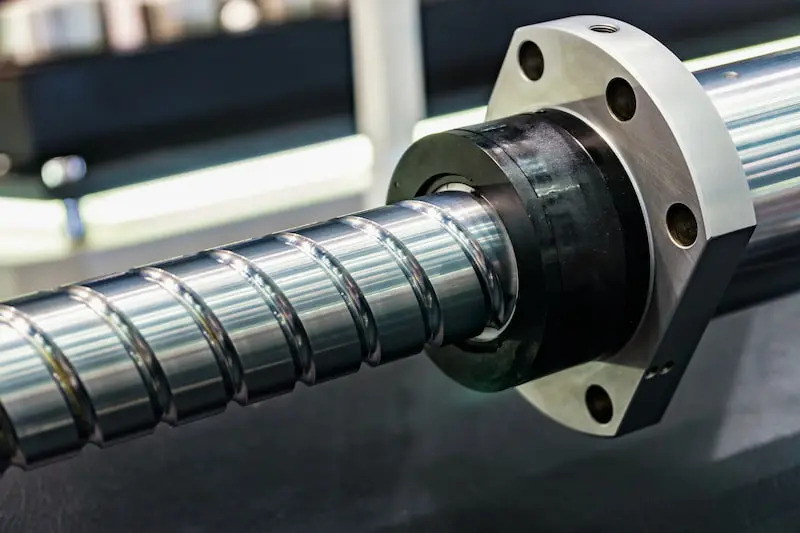

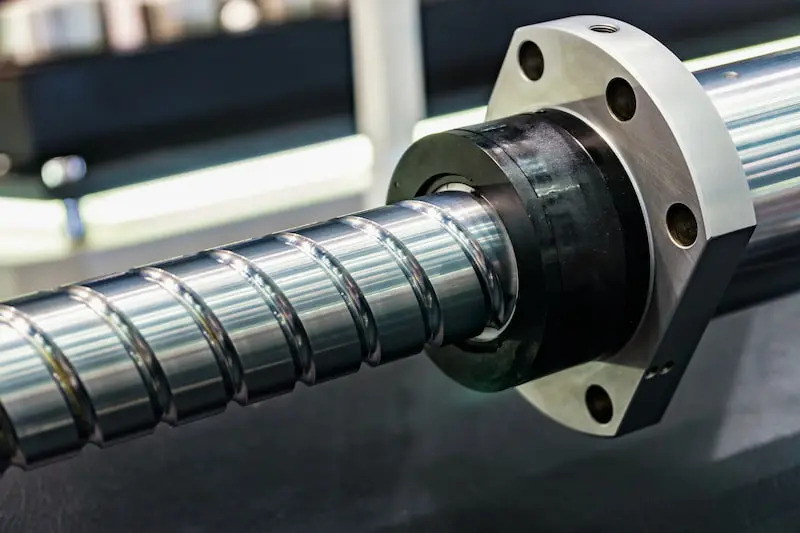

2.2 Bearing Compatibility

Having a smooth and polished shaft surface versus a rough shaft surface will vary the operation of the linear guide.

Different

linear bearings can be paired with shafts made from different materials to meet specific application demands or environmental requirements in the industry.

- Recirculating Ball Bearings: commonly paired with stainless steel or high-grade carbon steel coated shafts

- Plain Bearings: commonly paired with carbon steel, stainless steel, or aluminium plated shafts

The key thing is to operate recirculating bearings with well-polished shaft surfaces. This ensures more surface area and contact points between the shaft and the recirculating balls.

- Well-Polished Shaft: more surface contact area between the bearing and the shaft

- Rough Surface Shaft: less surface contact area due to an increase in surface irregularities

However, for plain bearings, it is much better to use a shaft with a slight rough surface. Using a smooth shaft would cause additional wear instead because plain linear bearings already have an existing self-lubrication function to help reduce friction.

How it works:

- Shafts with a slightly rough surface have slight micro-crevices on the surface

- Plain bearing balls have a higher number of peaks along the surface to transfer small bits of bearing material to the shaft

- This fills the crevices on the surface of the shaft, performing as a self-lubrication function

3. Shaft Hardness

Shaft hardness is a critical factor in the design and selection of linear motion systems for various reasons.

Importance of linear guide shaft hardness:- Wear Resistance: increase resistance to wear and abrasion, withstanding prolonged use without significant degradation while also maintaining performance levels

- Load Bearing Capacity: support higher loads without deformation

- Surface Finish: retains polished or ground surface finish better, ensuring smooth operation and low friction

- Dimensional Stability: resistance to deformation under load, ensuring the shaft maintains its shape and alignment

- Compatibility with Bearings: different shaft hardness are suitable for different types of bearings

3.1 Recirculating Ball Bearings

Shaft hardness is critical for recirculating ball bearings due to the handling of high loads. If the hardness values of the shaft are too low, it could result in damage to the shaft due to high stress.

3.2 Plain Bearings

Shaft hardness has an impact on the wear of plain bearings. This is due to the lack of seals or wipers, which results in contaminants lodging between the bearing and the shaft. If the shaft does not have sufficient hardness levels, the contaminants may end up getting into the shaft itself, resulting in quicker wear.

Pairing Your Linear Guides to the Right Bearings

Evaluating the different qualities of linear guide shafts is the best way to ensure you make the optimal match for your bearings and thus best decision for your linear motion system.

If you are still uncertain about linear guide shafts, SLS has

a team of professionals ready to assist in helping you find the right fit and fix for your industry and processes.

Alternatively, you may take a look at our extensive line of

linear guide shafts on our website.

Get in touch with us for professional assistance and streamlined operational efficiency today!

Contact Us

Contact Us