Deep groove ball bearings are the most widely used bearing type, known for their versatility. They have low friction and are optimized for low noise and low vibration, enabling them for high rotational speeds. They accommodate radial and axial loads in both directions, are easy to mount, and require comparatively less maintenance.

Deep groove ball bearings are essential components in many mechanical systems - due to their versatility and efficiency. They're designed to support axial and radial loads, making them suitable for several applications. They reduce friction and provide smooth, high-speed rotation. Their applications range from electric motors in household appliances to office machinery and car motors. They are usually easy to mount and require comparatively less maintenance. Deep Groove Ball Bearing: Components and Functions

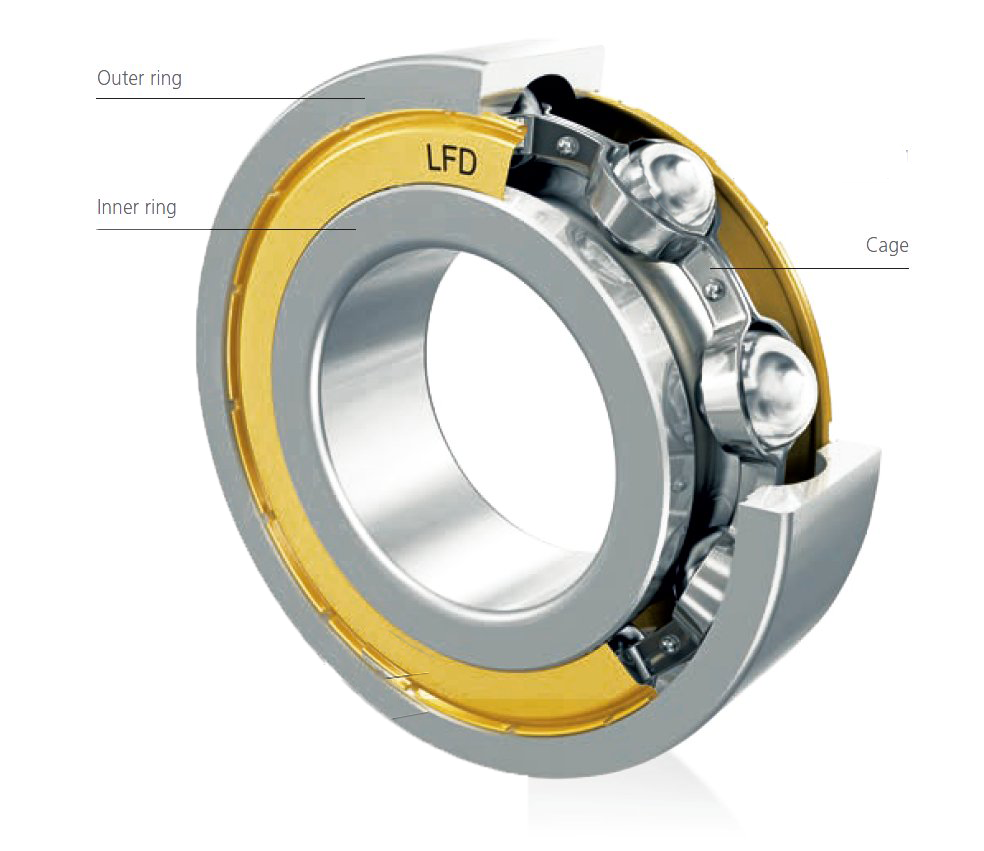

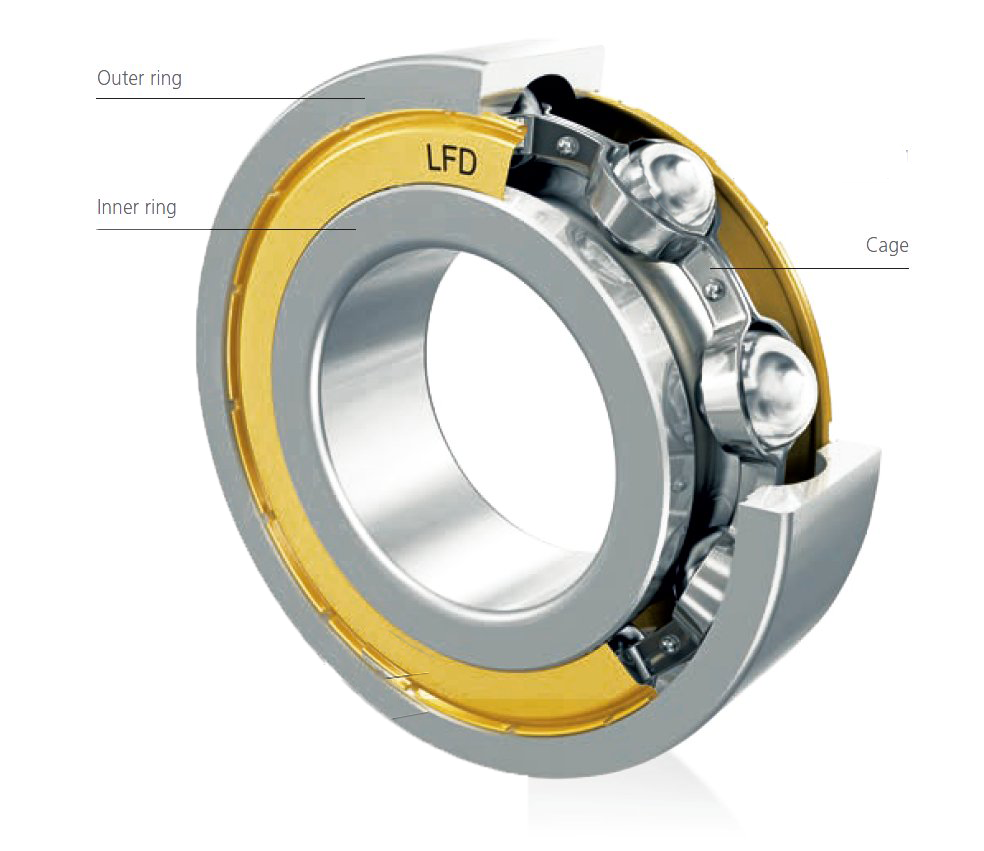

Outer Ring

The outer ring is the larger of the two rings. There is a groove on the inside diameter of the outer ring that forms a pathway for the balls. The outer ring is usually held stationary.

- Design: The outer ring consists of deep raceway grooves that match the contour of the balls, ensuring a smooth rotation and distribution of radial loads. The design is optimized to minimize friction and wear while maintaining the structural integrity of the bearing. The design of the outer ring also allows for efficient operation at very high speeds, making it suitable for high-speed applications.

- Features: Key features of the outer ring include its precision, manufacturing, and durability. The outer ring must withstand various operational stresses and environmental conditions without deforming or degrading. Additionally, snap rings are used on the outside diameter of the outer ring to secure the bearing in place.

- Materials: Common materials used for the outer ring include high-quality steels such as chrome or stainless steel. These materials are chosen for their strength wear resistance, and ability to handle high temperatures and corrosive environments.

Inner Ring

The inner ring is the smaller of the two bearing rings. The inner ring has a groove on its outer diameter to form a pathway for the balls. The surface of the outside diameter path is finished to extremely tight tolerances and is honed to a very smooth. The inner ring is mounted on the shaft and it’s the rotating element.

- Purpose: The main purpose of the inner ring is to provide a raceway for the balls in single row bearings, enabling smooth rotations and the ability to accommodate radial forced. this enables smooth rotations and load distribution. It ensures the bearing remains properly aligned with the shaft.

- Materials: Just like the outer ring, the inner ring is most commonly made from high-quality steels such as chrome or stainless steel. These materials provide the necessary strength and durability to handle operational stresses. Different bearing types are available, including single row deep groove ball bearings, SKF inch bearings, and bearings with a tapered bore.

- Surface Finish: The surface finish of the inner ring is crucial for reducing friction and wear and tear. A smooth, polished finish ensures efficient operation and longevity of the bearing. Surface treatments such as heat treatment or coating can also enhance performance and durability.

Cage

The main purpose of the cage is that it separates the ball, maintaining a constant spacing between the inner and outer rings.

- Ball spacing: The cage ensures that the balls are evenly spaced, preventing them from coming into contact with each other. This spacing reduces friction and wear, contributing the bearing's efficiency and lifespan by ensuring low frictional torque. The cage design also allows for efficient operation at high speeds, making it suitable for applications requiring rapid rotation and minimal friction.

- Alignment: The cage also helps in maintaining the alignment of the balls, ensuring that they move smoothly along the raceways of the inner and outer rings. Proper alignment is critical for minimising vibration and noise during operation. The importance of low noise cannot be overstated, especially in applications requiring quiet performance.

- Materials and Design: They are typically made from materials such as steel, brass, or synthetic polymers. The choice of material depends on the specific application and operating conditions. The design of the cage can vary, including ribbon, crown, or snap-in styles, each offering different performance characteristics.

In conclusion, deep groove ball bearings are essential components found in many industrial machines with each part playing a vital role in their performance. The outer ring, inner ring, and cage all work together to ensure smooth operation, load distribution, and durability. By understanding the design, materials, features, and functions can help in selecting the right bearing for specific applications and maintaining them effectively for prolonged use. As essential elements in numerous mechanical systems, deep groove ball bearings continue to be a cornerstone in engineering and manufacturing, driving efficiency and reliability in various industries.

For those seeking professional assistance or specialised expertise in dealing with deep groove ball bearings, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions to meet the unique needs of clients across various industries.

You can also browse our extensive

deep groove ball bearings selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Contact Us

Contact Us