Products & Services Industry Guides

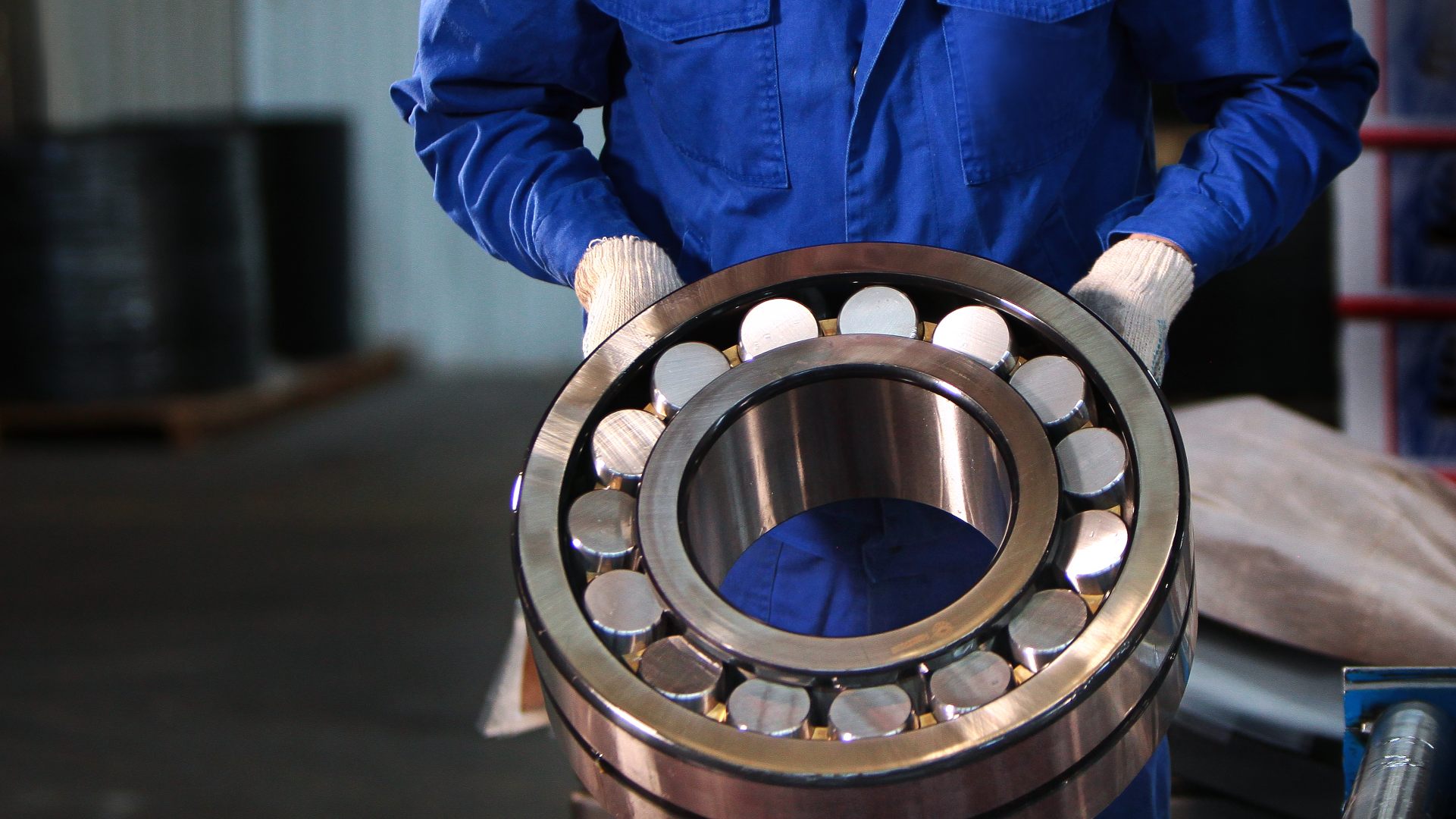

There are countless industrial applications for roller bearings as many industries require efficient motion in their machine equipment.

In addition, they are created unique as every type has a certain design that gives them a specialisation or characteristics for specific requirements.

This article will discover the specific applications of the main types of roller bearings and help you understand their various application.

Several main types are commonly used in industrial processes. Here are the examples:

Cylindrical Roller Bearings: They have high radial load capacity and are suitable for applications with high radial loads and moderate axial loads.

Tapered Roller Bearings: They have tapered rollers and raceways to handle moderate radial and axial loads efficiently.

Spherical Roller Bearings: They have barrel-shaped rollers and raceways, allowing them to accommodate misalignment and shaft deflection.

Needle Roller Bearings: They feature long, thin rollers with a high length-to-diameter ratio and are suitable for applications with limited radial space.

Roller bearings play a crucial role in various industries, including the oil refinery industry.

In this industry, companies employ them in a wide range of applications. Here is an overview of several applications:

Rotating Machinery: Oil refineries rely on numerous types of rotating machinery for various processes such as pumping, compressing, mixing, and agitating.

They are utilised in pumps, compressors, turbines, and other rotating equipment to support shafts and reduce friction between rotating and stationary components.

Conveying Systems: Roller bearings are integral components in conveyor systems used for transporting raw materials, intermediate products, and finished goods within oil refineries.

These bearings support conveyor rollers, pulleys, and shafts, allowing for efficient and reliable material handling throughout the refining process.

Crushers and Grinders: Oil refineries often utilise crushers and grinders to reduce the size of raw materials such as crude oil, coal, and catalysts.

Roller bearings are employed in these machines to withstand heavy loads, shock, and vibration, ensuring continuous operation and minimising downtime.

Heat Exchangers and Fans: Heat exchangers and fans are critical for controlling temperatures and facilitating heat transfer in various refining processes, including distillation, cracking, and desulfurization.

Roller bearings are used in the rotating shafts of fans and the supporting structures of heat exchangers.

Storage Tanks and Vessels: Roller bearings are utilised in the floating roofs, access bridges, and other moving components of storage tanks and vessels within oil refineries.

Centrifugal Separators: Centrifugal separators are essential equipment in oil refineries for separating different components of crude oil and other fluids based on density differences.

Roller bearings support the rotating components of centrifugal separators, enabling high-speed operation while maintaining stability and precise separation.

From traditional fossil fuel-based facilities to renewable energy installations, here's an overview of roller bearing applications in the power generation industry:

Turbine Systems: Roller bearings play a critical role in supporting the shafts of turbines used in steam, gas, and hydroelectric power generation.

These bearings are employed in steam turbines, gas turbines, and hydro turbines to withstand high-speed rotation and heavy loads, ensuring smooth operation and efficient energy production.

Generator Sets: Power generation facilities rely on generators to convert mechanical energy into electrical energy. Roller bearings are used in generator sets to support the rotating components, including the rotor and stator.

These bearings facilitate smooth rotation, reduce frictional losses, and maintain alignment, contributing to reliable and stable electricity generation.

Gearboxes and Drives: Roller bearings are utilised in gearbox assemblies to support shafts, gears, and other rotating elements, providing high load capacity and low friction operation for efficient power transmission.

Renewable Energy Systems: In addition to traditional power generation facilities, roller bearings are used in various renewable energy systems, including wind turbines and solar power plants.

In wind turbines, roller bearings support the rotor shaft and blade pitch mechanisms, enabling efficient energy capture from the wind.

In solar power plants, roller bearings are employed in tracking systems to support solar panels and ensure optimal alignment with the sun for maximum energy output.

Other than the previous industries mentioned, roller bearings serve critical functions in various heavy machines, including agriculture machinery, construction equipment and aerospace systems:

Agriculture Machinery: In agriculture machinery such as tractors, combines, and tillers, roller bearings support rotating shafts, wheels, and implements.

They reduce friction and wear, allowing for the smooth operation of components like axles, spindles, and transmission systems.

Construction Equipment: Excavators, cranes, and bulldozers, roller bearings support rotating components such as boom arms, tracks, and gears.

They enable smooth movement of moving parts under heavy loads, ensuring precise control and efficient operation of construction machinery.

Aerospace System: Bearings are extensively used in the aerospace industry, as stated by matec-conferences.org, to the extent that their performance will directly affect the industry's efficiency and safety. For instance, it is used in aircraft engines to support rotating shafts, such as those in turbine engines, propeller gearboxes, and auxiliary power units (APUs).

In conclusion, roller bearings stand as indispensable components across a multitude of industries, serving as the backbone of efficient mechanical systems.

Understanding the functions of roller bearings is crucial for anyone involved in machinery design, maintenance, or repair.

However, choosing the right roller bearings can be complex, especially in specialised or high-demand applications.

So, if you need assistance or facing any problems with your roller bearings, you can consult our team of experts in SLSPRO.

You can also browse our extensive selection of roller bearings products on our website.

Get in touch with us for professional help and greater operational efficiency!

Essential components ensure smooth and efficient rotational motion in machinery.

Find Out MoreEssential components ensure smooth and efficient rotational motion in machinery.

Find Out More

Contact Us

Contact Us