Products & Services Industry Guides

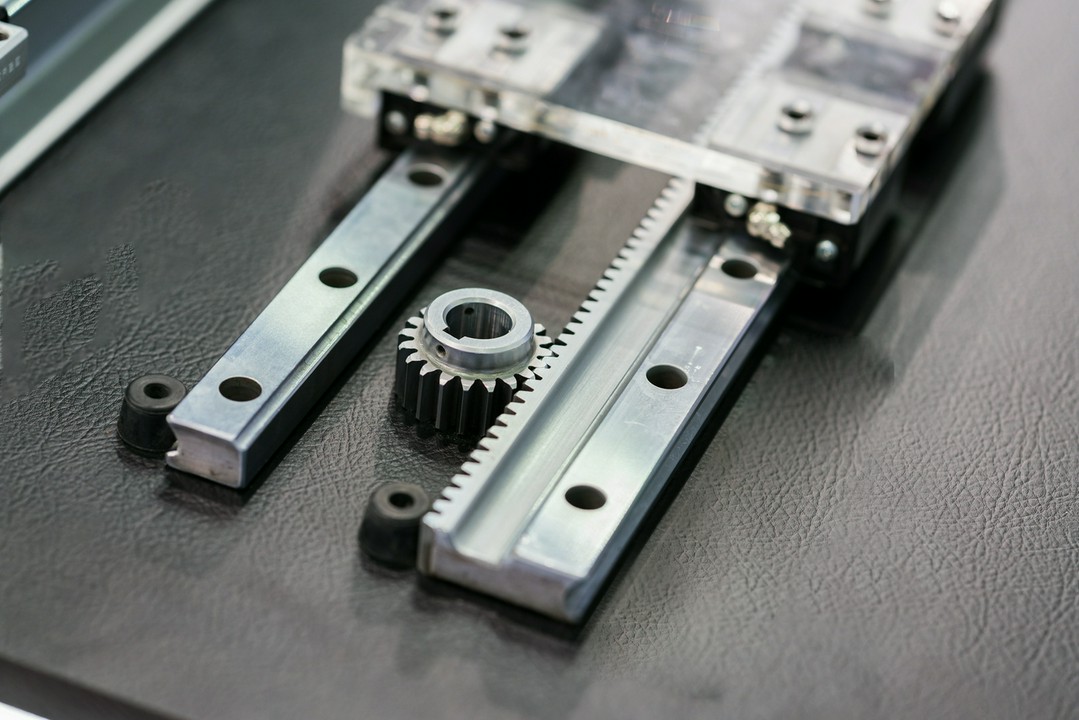

A round linear guide, also known as ball bushing, is the older technology as compared to the square linear guide, designed to enable precise and controlled linear motion within various linear guide rails systems. It has been around for 80 years and commonly has a lower load capacity and looser accuracy for an economical option in its line of production.

This ball guide attribute can either be its strength or weakness depending on the application in the linear system. For starters, where loose tolerances are acceptable or saving on component cost is more critical than tight tolerances, this will be an excellent choice.The roundness of ball guides helps to distribute the load more evenly, an attribute that is shared with the cylindrical rollers in roller bearings.

The smooth and consistent motion provided by the linear bearings is also one of their key feature which allows a uniform movement between the guide rail and the rolling elements. This can be credited to the circular track employed in the linear bushing that makes them just the suitable machine tools for specific applications.

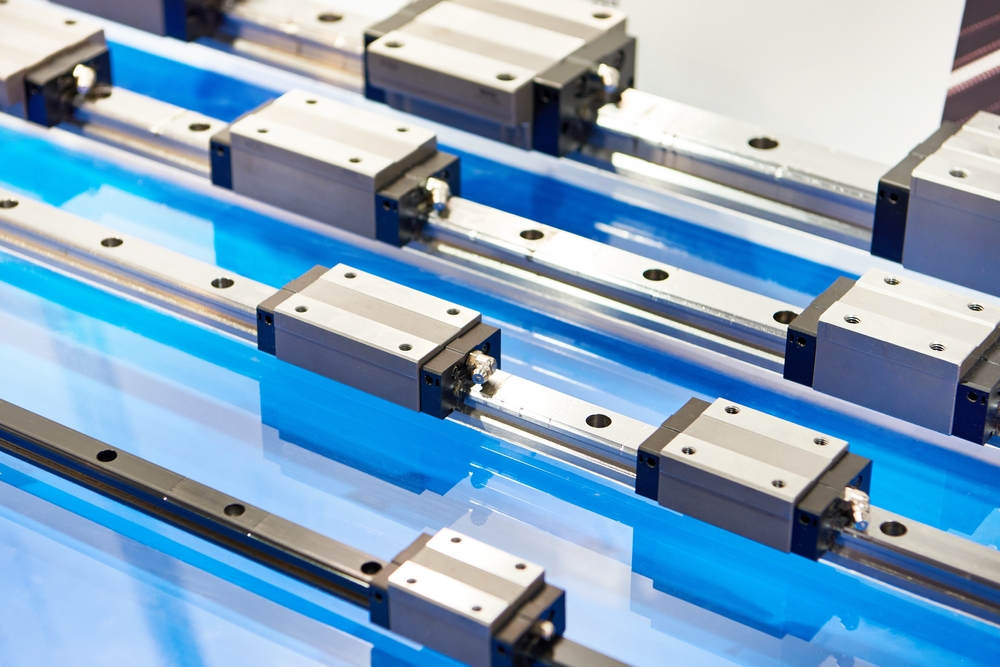

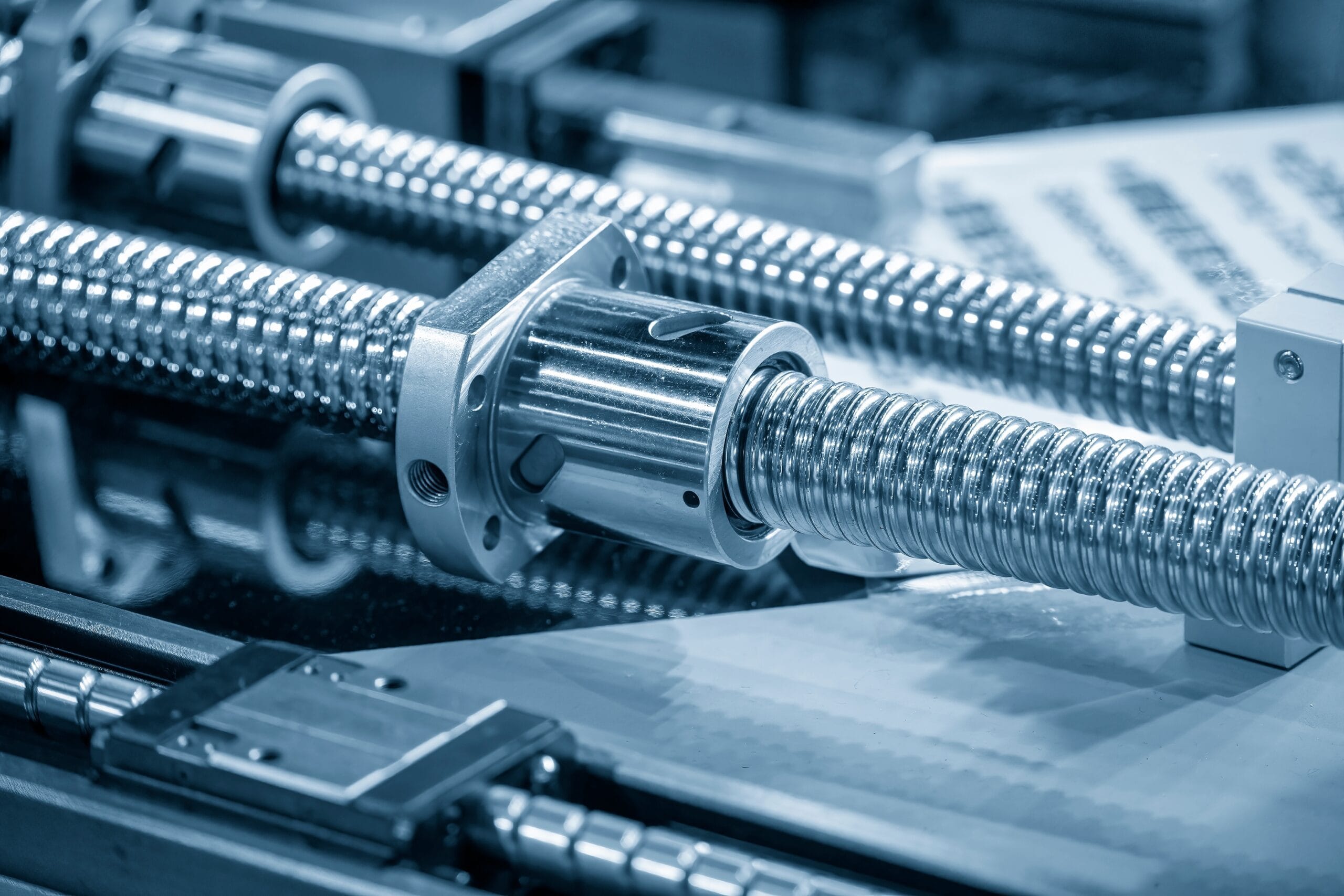

Square linear guides or best known as profile rails represent a foundational component in the realms of linear motion systems and of course, an efficient solution in mechanical engineering. Unlike the round linear guides, profile rails are the newer counterparts of the systems and have been utilised for 40 years in facilitating parts in machinery such as semiconductor manufacturing equipment.

What sets it apart from the round or ball guides is its strength. Profile Rail Linear Guides' strength lies in its robust capability to support more loads. The rectangular track design provides larger contact surfaces which enhances the stability of the linear rails, making it well-suited for a carriage containing heavy loads.

While linear guide rails are generally utilised for maintaining accuracy and repeatability of motion, this model stands out as a prominent component where rigidity and precision are needed. Due to its square geometry, square linear guides provide structural integrity suitable to handle high loads that demand consistent and accurate performance.

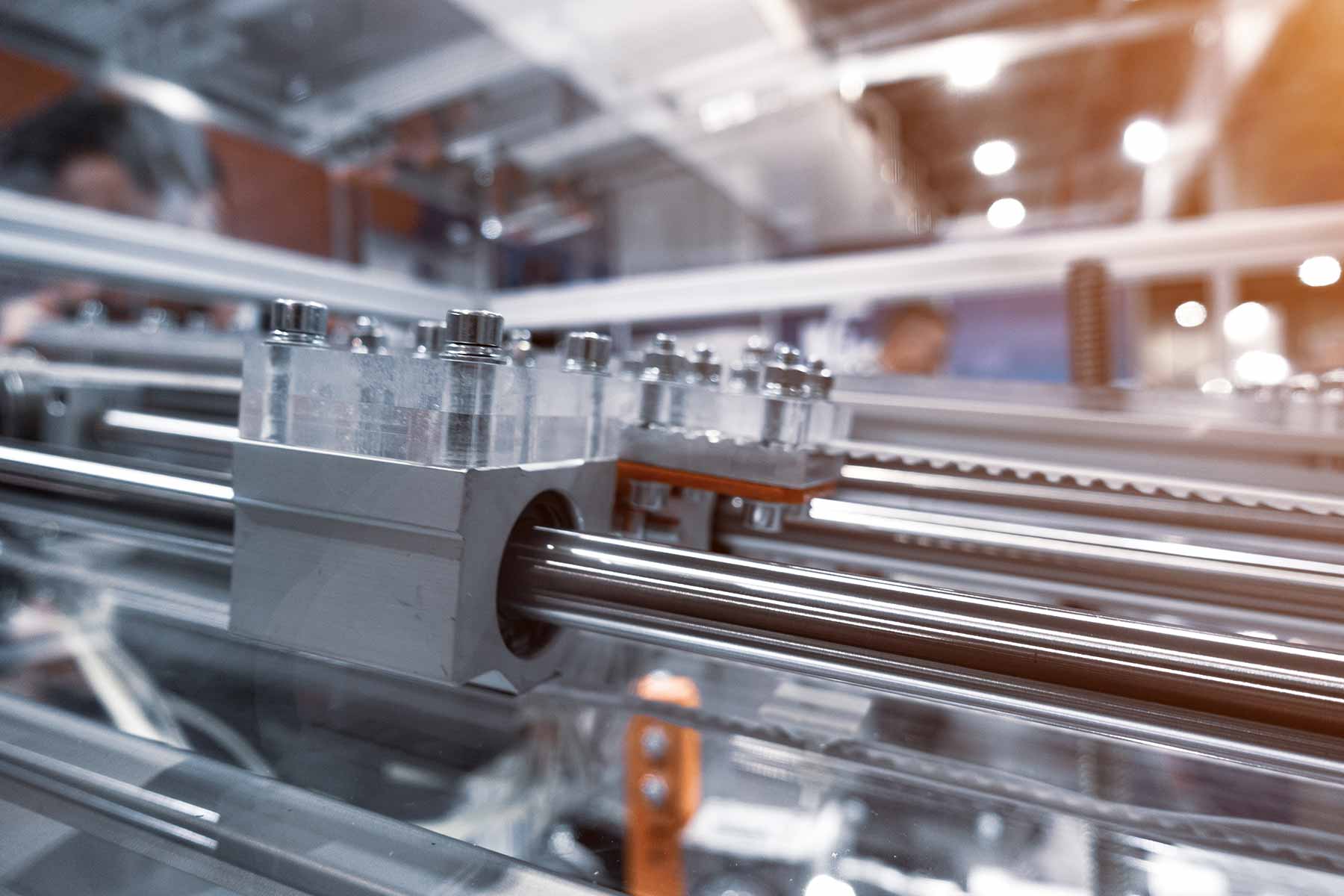

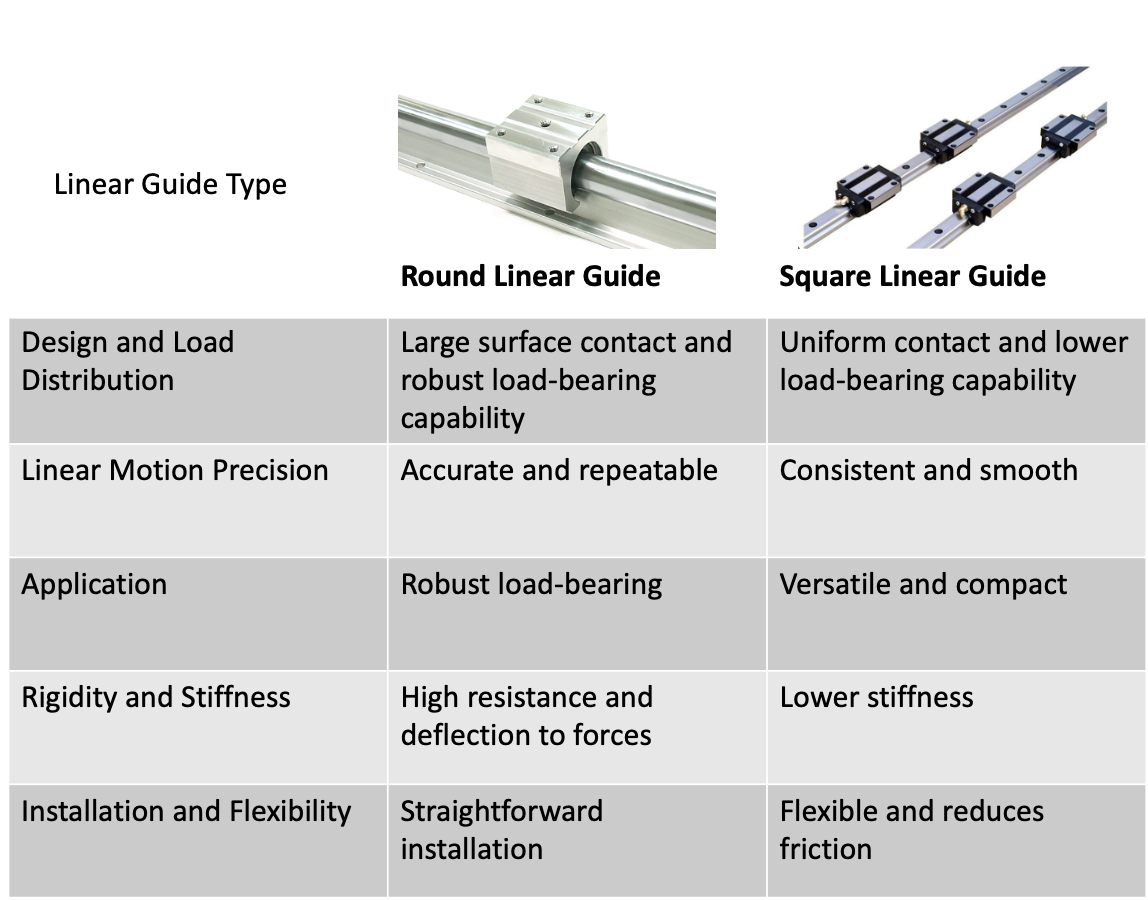

Both round and square linear guides are compact machine tools of two distinct designs created for mechanical and industrial applications of precise and controlled linear motion. These two linear bearing systems facilitate various mechanical and industrial sectors by enhancing machine efficiency. Despite sharing the common goal of facilitating the mechanical industry, these two technologies have a few attributes that set them apart as well.

Each type of linear guide rail offers unique characteristics for specific operational needs. Here are a number of comparisons between square and round linear guides in terms of design and load distributions, linear motion precision, application, rigidity, and installation.

Profile rails feature a rectangular track design which provides larger surface contact between the rolling elements and guide rail. This design is optimised for a wider range of load-bearing capabilities and mounting forces.

Profile rails have a structure that is inherently resistance to forces due to its rectangular track. This ensures an accurate and repeatable linear motion, fit for high-demanding accuracy industries such as CNC machining and semiconductor machinery.

Round linear guides offer a lower precision as compared to the profile rail type but in exchange, it features more flexibility. The circular-shaped component also gives a more consistent and smoother movement as compared to square ones under certain conditions.

Profile rails which possess a robust load-bearing capacity are commonly used in heavy-duty applications such as machine tools in industrial automation due to their rectangular structure. It is also mainly used in any environment which requires accuracy with a heavy load.

Round linear guides have a versatile and compact nature fitting for when space is limited and where aesthetics are one of the concerns. Electronic assembly or machines in the medical industry are some examples where they can be used.

Profile rails feature higher resistance to deflection of torsional forces that provides greater rigidity and stiffness to its motion. This ensures the movement in machines remains accurate even in demanding environments.

Round linear guides with their circular track exhibit lower stiffness as opposed to the rigid structure of the miniature guides in the picture above. This resulted in a lower load-bearing capacity, which will be affected under harsh or heavy loads and forces.

Profile Rails has a straightforward installation regardless of the rail length and a variety of mounting options to choose from. Their rectangular profile also allows some degree of flexibility especially involving existing equipment with unique spatial constraints.

Round linear guides operate with a compact design that resembles that of circular linear bearings which reduces friction to its movement. This configuration means more flexibility and simpler installation for it, albeit less mounting variety as compared to a square one.

Fundamentally, there are both pros and cons with round and square linear guides. The uniform contact, smoother motion, and reduced friction from round linear guides make it a better fit for seamless movement. In addition, the round rails are more cost-effective and more tolerant in a looser condition. However, these features limit the mounting options and a lower bearing load capability altogether.

Whereas square linear ones are intended for higher consistency and accuracy with robust mounting options, that resulted in a wider load-bearing range. Their rectangular design also is integral for load distribution and provides reliable support for linear motion. However, it carries a lower aesthetic profile.

Therefore, both technologies can be reliable depending on the operation and parameters involved in the user's need themselves. One thing to remember is understanding the strengths of each model, price range, and aesthetic. This is important for engineers and designers in order to make an informed decision, to ensure the best system is chosen for any given application.

Head over to our Linear Guides product page for more details or contact our dedicated product experts who will provide recommendations and the relevant information you need!

Precise tracks ensure smooth and accurate linear motion in machinery.

Find Out MorePrecise tracks ensure smooth and accurate linear motion in machinery.

Find Out More

Contact Us

Contact Us