Products & Services Industry Guides

An autonomous robot is a robot designed and programmed to handle tasks on its own for long periods of time without requiring human intervention or extended supervision.

This article will cover the key ways to utilise autonomous robots into your industrial processes, such as using data to streamline operations, improved safety measures and the long-term investments.

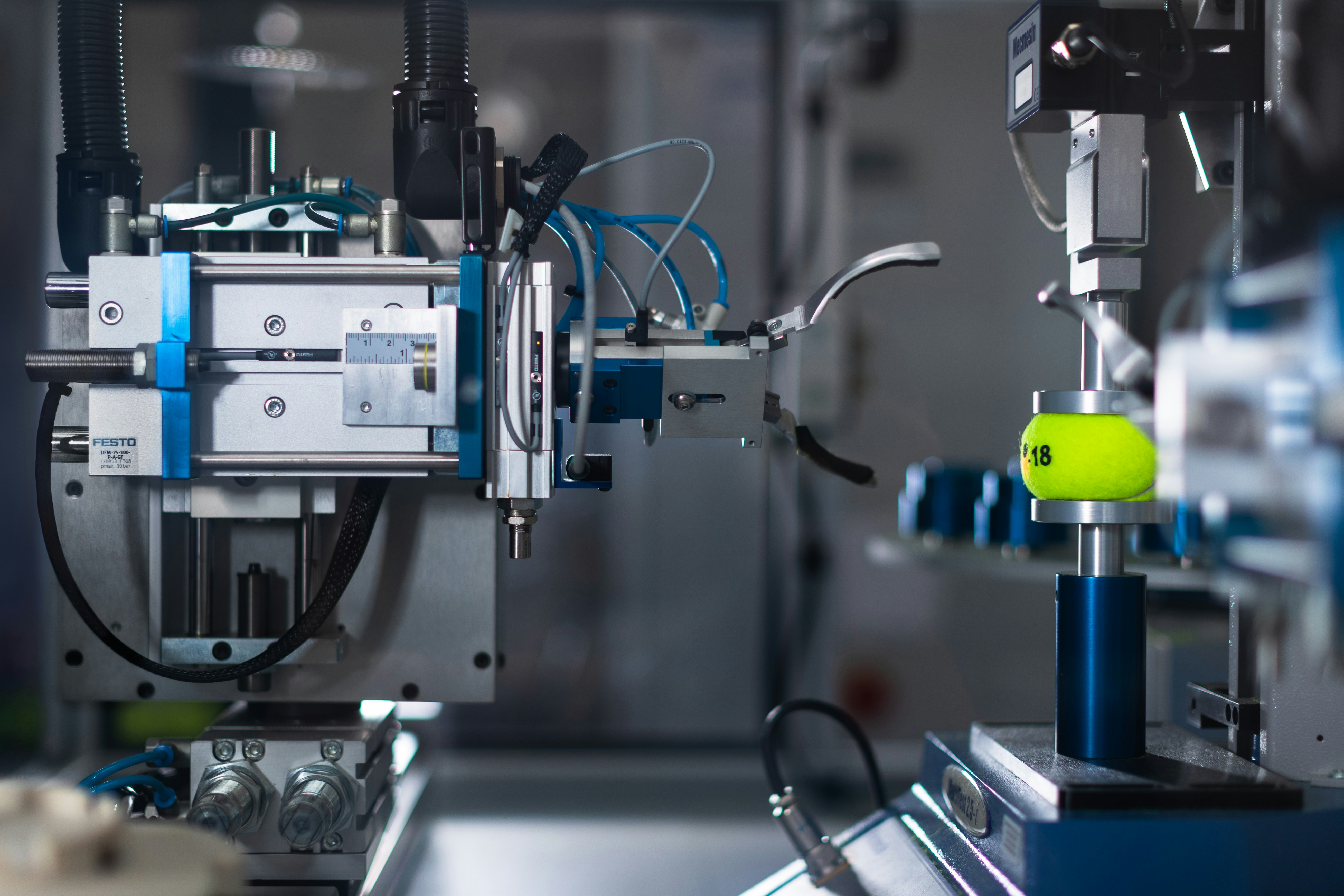

Autonomous robots have become an integral part of industrial processes since their introduction and have only been improving as technology advances over time. They have the ability to complete their task without human interaction, unless that human interaction is necessary in their task.

Their benefits to improving supply chain operations and manufacturing industries have been indisputable, with industries utilising them in their workflows to enhance the workplace; cutting down on repetitive and complex tasks done by humans, allowing them to not only have improved safety measures but also to focus on more strategic tasks.

The collaboration of human expertise and automation robotics have sparked the term ‘cobots’, or collaborative robots that assist humans.

An autonomous mobile robot is programmed to move around independently from human control.

These robots are used for production and sorting purposes; picking up, putting away, replenishing and keeping inventory of stock. To maximise the utility of these robots, data collection and artificial intelligence plays a big part.

These robots use machine learning to adapt to the environment independently thanks to their advanced mapping capabilities.

This usage of navigational data allows them to not only map out the entire working facility, but also do regular upgrades to their navigation so that they are always up-to-date with the most efficient routes.

Automated package handling allows cobots to not only optimise and increase efficiency in packing and handling, but also do automated documentation of the packages to allow for easy tracking and digital tracking to ensure optimal operation for supply chains.

With the power of robotic simulation, advanced softwares can be used to model virtual representations of production lines to collect useful data. This will help find the optimal process that will help minimise downtime and do early interventions on possible errors through the flexibility of adjusting different scenarios.

Find out more about SLS Robotic Simulation Capabilities here.

One of the key benefits of autonomous mobile robots and cobots in industrial processes is their ability to handle laborious and repetitive tasks in high-risk manufacturing environments. This heavily reduces involvement of human workers in dangerous working environments, such as material handling and manufacturing, food processing and chemical processes.

Utilise these features to ensure your workplace is a safe and efficient environment for the optimal process:

Autonomous mobile robots are equipped with floor sensors that slow down or stop them when they are too near obstacles. This prevents them from colliding into humans, or damaging surrounding structures or other robots.

There are different types of environment sensors that these autonomous robots use, such as:

Ultimately, they share the common function of allowing the robot to avoid obstacles in the environment in order to efficiently and safely execute their tasks.

In the event where it suddenly gets obstructed or if a technical issue occurs where the autonomous robot does not detect the same image it had seen from previous operations in the area, the robot is programmed to stop and the system will indicate that there is an error.

From there, some robots are able to reroute to a different route in order to continue operations.

While the initial costs to introduce automation solutions to the warehouse may appear frightening, there is a long-term investment that comes with utilising robotic automation and cobots in your processes.

The usage of autonomous robots helps to lower costs through varying means. Not only are modern autonomous robots more efficient, they also have higher performance capabilities. Cobots are able to work longer periods with little maintenance, and are able to show diagnostics to predict when maintenance is necessary, which helps to lower the overall costs.

Autonomous robots are capable of performing tasks with high precision, performance and consistency, reducing the likelihood of errors and defects. This not only reduces the likelihood of reworks and waste, but also improves fulfilment of customer demand and can improve revenue.

In conclusion, there are many benefits autonomous robots can bring to your industrial process. It is key to know these benefits to utilise them to your business' advantage and find the right solution for you.

If you are still uncertain about how to utilise autonomous robotics to upgrade your current systems, SLS Bearings has an extensive team of experts with knowledge of robotic automation solutions for varying industrial sectors ready to assist you to find the right solutions to your needs.

You can also view our line of autonomous robotic arms here on our website.

Get in touch with us for professional assistance and streamlined operational efficiency today!

Explore Kassow Robots' innovative 7-axis cobots for versatile industrial applications. Precision, safety, and modularity.

Find Out MoreExplore Kassow Robots' innovative 7-axis cobots for versatile industrial applications. Precision, safety, and modularity.

Find Out More

Contact Us

Contact Us