Products & Services Industry Guides

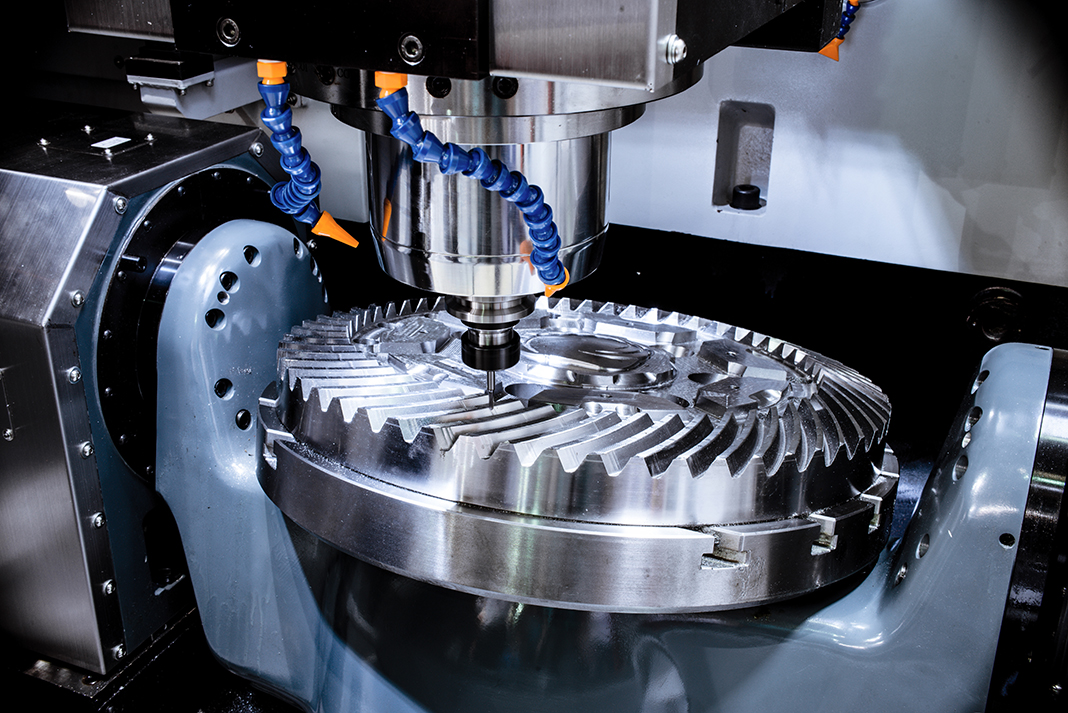

Precision machinery is used in various industries requiring accuracy, including aerospace, automotive, mining and laboratories.

Some widely used precision machinery examples include CNC (Computer Numerical Control) machines, semiconductor manufacturing equipment and precision cutting tools.

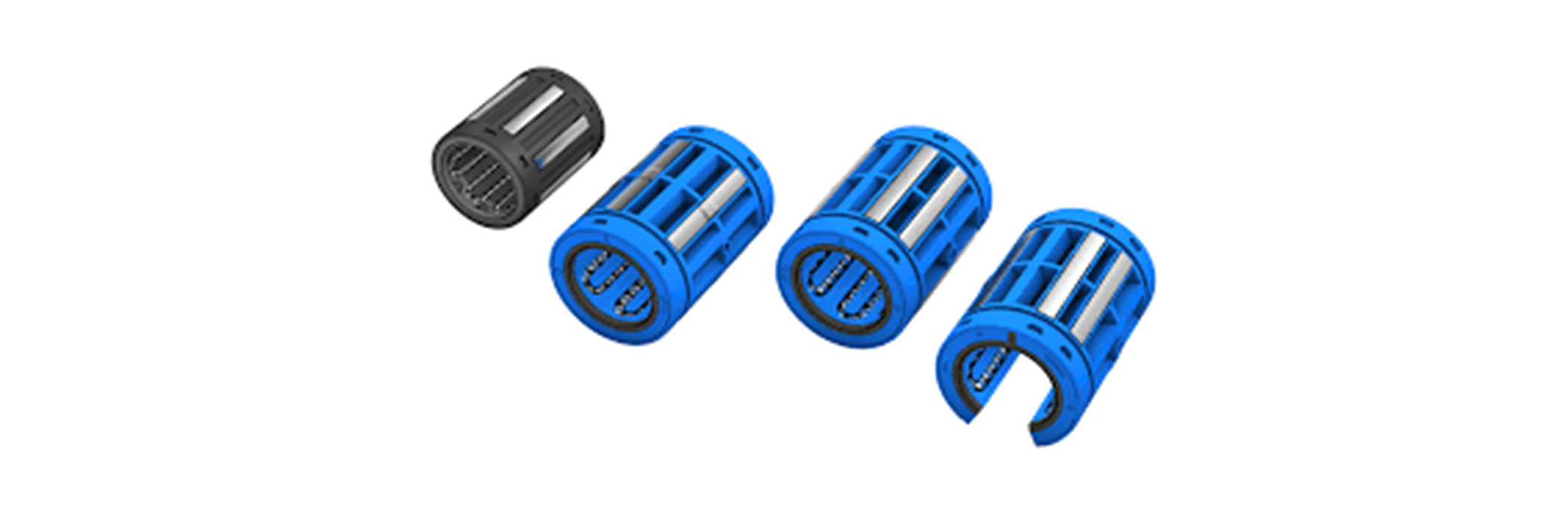

Linear bearings are essential in precision machinery as they directly contribute to machine performance accuracy.

This article will explore the role of linear bearings in precision machinery by addressing their importance and real-life applications in different industries.

Linear bearings ensure the machine's optimal performance by guiding moving components along a linear path with precision, minimising deviation and maintaining alignment.

This mechanical component also provides stability, reduced friction, and high load-carrying capacity which contribute to the longevity of precision machinery systems.

Some of the linear bearings' characteristics which make them important are as below:

Linear bearings are designed to provide stability and rigidity to precision machinery, ensuring that it operates reliably regardless of which industries it was used for.

This stability and rigidity can be traced back from its damping effects, stiffness and guided motion as below:

Damping Effects: Some linear bearings are designed with damping properties that help absorb and dissipate vibrations generated during operation. By damping vibrations, linear bearings further enhance the stability and rigidity of precision machinery, improving overall performance and accuracy.

Guided Motion: Linear bearings guide the motion of moving components along a linear path with precision. By providing a predefined path for motion, linear bearings help prevent unwanted movements or vibrations that could compromise the stability of the precision machinery.

Stiffness: Linear bearings exhibit high stiffness, resisting deformation under load. This stiffness contributes to the rigidity of the machinery, ensuring that it maintains its structural integrity even when subjected to external forces or loads during operation.

Linear bearings have several key mechanisms that ensure a smooth motion is produced by reducing friction for machine repeated movement.

The friction is reduced due to how it is engineered with smooth surface contact, sealing and protection, and precision manufacturing.

Linear bearings are often made from materials with low coefficients of friction, they give a smooth contact surface between moving components, minimising frictional resistance.

In addition, sealing and protection also assist in reducing frictional wear by preventing foreign particles from entering the bearing assembly.

This guarantees smooth operation and according to sciencedirect.com, prevents grease from leaking out making for a more efficient lubrication.

Lastly, linear bearings are manufactured with tight tolerances and precision machining techniques to ensure smooth and precise movement.

All these characteristics are important to precision machinery as less friction translates to low friction, lower energy consumption, quieter operation, and less wear and tear on the bearing components, resulting in increased efficiency and longevity of the machinery.

In a linear bearing, the component primarily responsible for load capacity is the bearing raceway or sliding surfaces.

Additionally, the overall design of the linear bearing assembly, including the housing or carriage that supports the bearing, also plays a role in load capacity.

Since precision machinery often involves moving components such as slides, rails, or shafts that carry the workpiece or cutting, linear bearings with high load capacity provide robust support for these components.

It ensures the machine can withstand the weight of the load without deformation or failure. This is required in numerous machines such as robotic assembly systems, metrology systems and high-precision laser cutting machines, to name a few.

To highlight the versatility and importance of linear bearings in various industries and applications, here are a few real-life examples of linear bearing applications.

In 3D printing, linear bearings are used to facilitate the precise movement of print heads, build platforms, and other moving components in 3D printers. Here's how linear bearings are utilised:

Print Head Movement: Linear bearings guide the movement of print heads along the X, Y, and Z axes, allowing for precise deposition of printing material layer by layer to create three-dimensional objects with intricate geometries.

Build Platform Adjustment: Linear bearings support the movement of the build platform, allowing it to move vertically or horizontally to accommodate different printing tasks and ensure optimal adhesion and accuracy during the printing process.

Linear Motion Systems: Linear bearings are integrated into linear motion systems, such as linear guides and rails, to provide smooth and precise linear motion for moving components in 3D printers, ensuring consistent and high-quality printing results

In industrial automation, linear bearings are essential components in various motion control systems, such as robotic arms, pick-and-place machines, and automated assembly lines. Here's how linear bearings are used:

Robotic Arms: Linear bearings support the smooth and precise movement of robotic arms along multiple axes, allowing them to perform tasks such as material handling, welding, and assembly with high accuracy and repeatability.

Pick-and-Place Machines: Linear bearings guide the movement of pick-and-place mechanisms, enabling them to pick up parts from one location and accurately place them in another, facilitating efficient and automated manufacturing processes.

Automated Assembly Lines: Linear bearings support the movement of conveyor belts, gantry systems, and other automated components in assembly lines, ensuring smooth and reliable operation as products are assembled and processed.

Conveyor Systems: In conveyor systems, linear bearings support and guide the movement of conveyor belts, rollers, and other moving components, facilitating the efficient transport of materials within manufacturing facilities. Here's how linear bearings are employed:

Roller Conveyors: Linear bearings support the rollers that carry the conveyor belt, ensuring smooth and reliable movement of materials along the conveyor line, from loading to unloading points.

Belt Conveyors: Linear bearings support the pulleys and drive systems that move the conveyor belt, enabling precise control of belt speed and tension to optimise material handling and throughput.

Automated Sorting Systems: Linear bearings guide the movement of sorting mechanisms, such as diverter arms and pushers, allowing for accurate sorting and routing of materials based on predefined criteria.

In conclusion, linear bearings play a fundamental role in ensuring the smooth, precise, and reliable motion of moving components in various types of machinery, ranging from industrial automation systems to 3D printers and conveyor systems.

By learning about linear bearings, machine operators gain valuable insights into how these components contribute to the overall performance, efficiency, and longevity of their equipment.

Alternatively, for those seeking professional assistance or specialised expertise in dealing with linear bearings, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and specialised services to meet the unique needs of clients across various industries

You can also browse our extensive linear bearing selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Precision-engineered linear bearings solutions for smooth operation and optimal performance.

Find Out MorePrecision-engineered linear bearings solutions for smooth operation and optimal performance.

Find Out More

Contact Us

Contact Us