Collaborative robotic arms, commonly referred to as "

cobots", are reshaping automation by allowing close, safe interaction between humans and robots. Unlike traditional industrial robots, cobots are designed to operate directly alongside human workers, supporting a wide range of tasks across industries. This article explores the key benefits, features, applications, and future trends of collaborative robotic arms.

What Are Collaborative Robotic Arms?

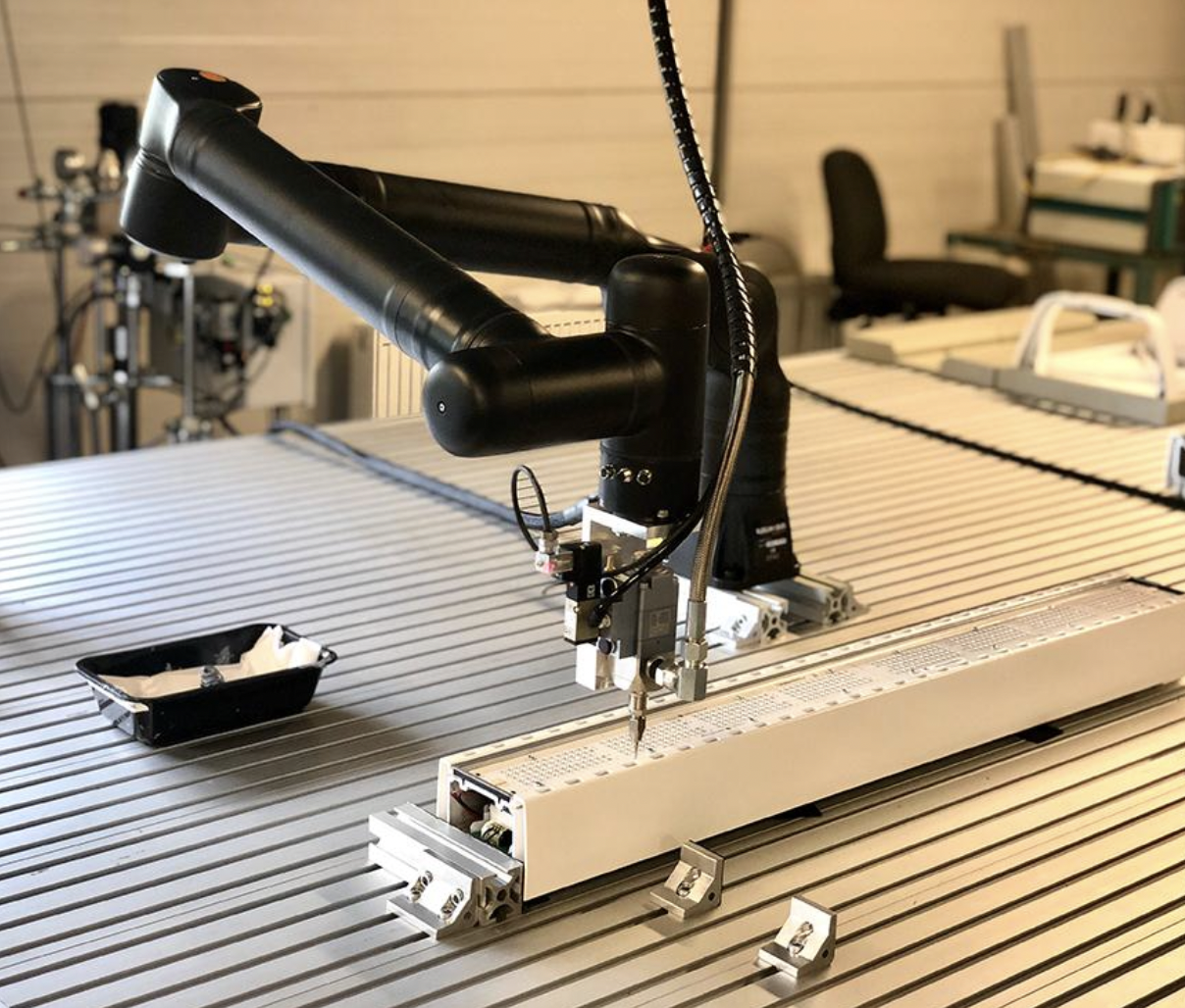

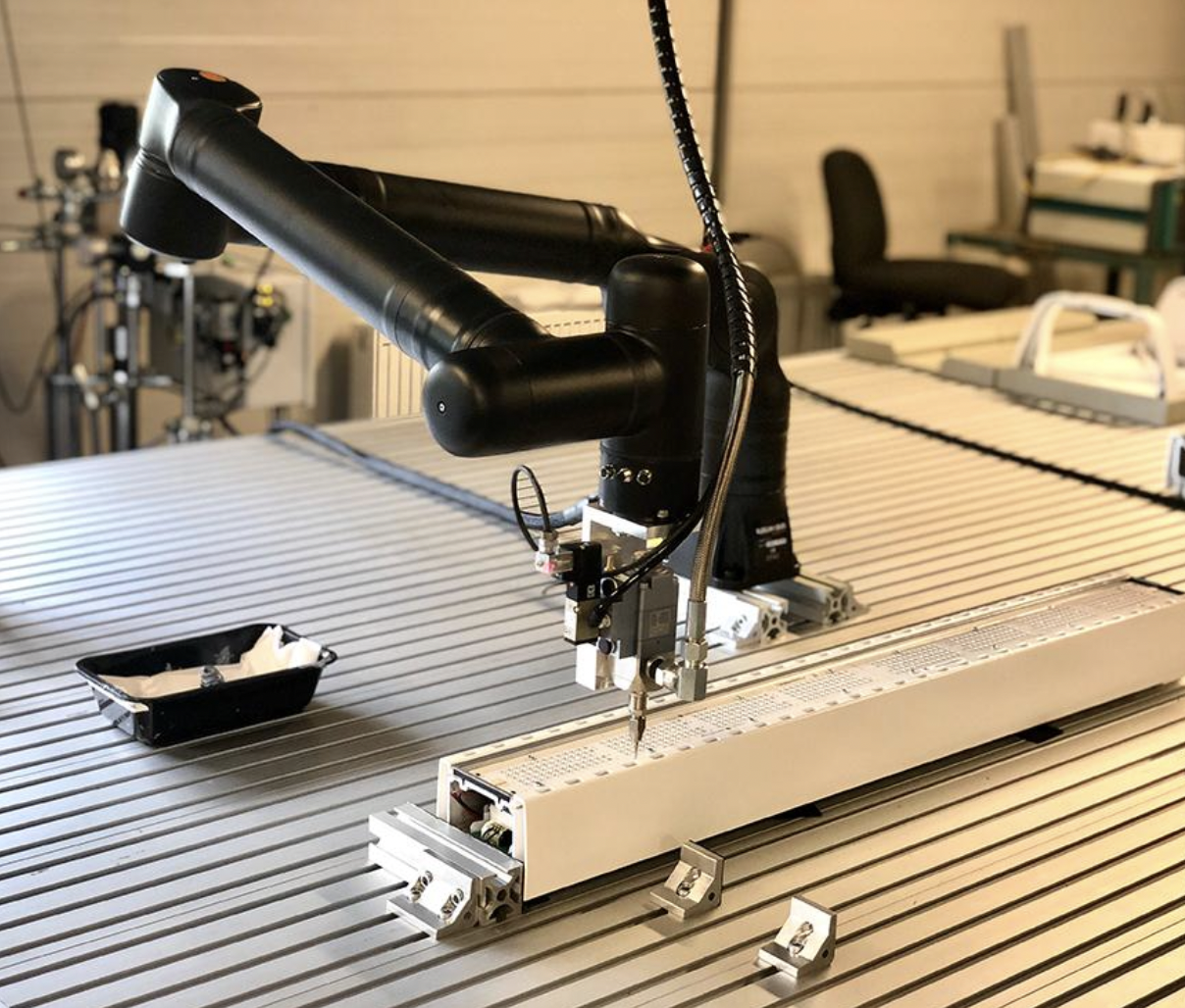

Collaborative robotic arms are robots engineered for safe, human-friendly interaction. Equipped with advanced sensors and safety features, cobots can perform tasks right next to human workers without the need for barriers. They are smaller, more adaptable, and often easier to program than traditional robots, which make them especially useful in industries that demand flexibility and adaptability. Cobots can also automate processes, particularly repetitive tasks, enhancing overall efficiency.

Key Benefits of Collaborative Robotic Arms

- Increased Efficiency and Productivity: Cobots excel at handling repetitive and high-precision tasks, such as assembly and inspection. This frees up human employees for more complex work, resulting in faster workflows and higher productivity. Additionally, then can manage and streamline thousands of automated workflows, integrating various tools and techniques to optimise business processes. Their ability to work continuously enables companies to maximise operational hours.

- Enhanced Safety: Cobots are designed with safety in mind, featuring sensors and collision-detection systems that stop the robot if it encounters an obstacle. This capability minimises the risk of workplace accidents, allowing robots and humans to work side by side safely, even in high-traffic areas.

- Flexible and Adaptable Operations: Unlike traditional robotic process automation that require dedicated programming and setup, cobots are easy to reprogram and redeploy for different tasks. This adaptability makes them ideal for industries with dynamic workflows or seasonal demands.

- Reduced Operational Costs: While cobots involve an upfront investment, they provide a fast return on investment by enhancing productivity, reducing labour costs, and minimising errors. Cobots require less space, have minimal maintenance needs, and don't require extensive setup, making them cost-effective, especially for small to medium-sized enterprises.

- Higher Job Satisfaction: Cobots handle monotonous and physically taxing tasks, allowing employees to focus on more engaging and creative responsibilities. This leads to a more fulfilling work environment, improving morale and job satisfaction among workers.

Core Features of Collaborative Robotic Arms in Automated Workflows

- User-Friendly Programming: Most cobots feature intuitive programming options, such as drag-and-drop interfaces or "teach-by-demonstration" methods, allowing even non-technical staff to operate them. This easy programming approach helps businesses save time and resources during setup. Additionally, these cobots can interact with digital systems, mimicking human actions to efficiently perform a variety of tasks.

- Advanced Safety Mechanisms: Cobots are equipped with sensors that detect human presence and adjust operations accordingly. If a cobot detects an obstacle, it stops or slows down, ensuring safety and compliance with workplace safety regulations.

- Compact and Lightweight Design: Cobots are designed to be portal and compact, making them ideal for small spaces for crowded environments. Their lightweight structure allows for easy integrations and redeployment as workflow needs change.

Real-World Applications of Collaborative Robotic Arms in Business Processes

- Manufacturing and Assembly: Cobots are increasingly used in manufacturing to handle tasks such as assembly, welding, and quality inspections. Their robotic process automation ensures high-quality output in industries like automotive and electronics.

- Packaging and Logistics: In warehouses and distribution centres, cobots perform tasks like sorting, packaging, and palletizing. By handling these repetitive tasks, they speed up the process and improve accuracy in sectors such as retail, e-commerce, and food distribution.

- Healthcare and Laboratory Work: Cobots assist in healthcare settings by handling tasks like sample preparation, lab testing, and even patient assistance. The precision and ability in their robotic process automation in sterile environments make them valuable for routine yet critical procedures in hospitals and research labs.

Future Trends in Collaborative Robotics and Advanced Technologies

- AI Integration for Enhanced Functionality: The integration of artificial integration (AI) with cobots is advancing rapidly, allowing cobots to perform more complex, data-driven tasks. AI enables cobots to learn from past actions and adapt to new tasks with minimal reprogramming, making them even more versatile.

- Improved Human-Robot Interaction (HRI): With developments in voice and gesture recognition, future robots will be able to interact more intuitively with humans. These enhancements will make cobots even easier to use and further improve the collaboration between human workers and robots.

- Increased Adoption Among Small and Medium Enterprises (SMEs): As cobot technology becomes more affordable, SMEs are expected to adopt these robots at a higher rate. This flexibility, ease of use, and affordability of cobots make them accessible to businesses of all sizes, especially those that may not have the resources for full-scale automation.

Collaborative robotic arms are revolutionising the way industries approach automation. By enabling safe and efficient human-robot collaboration, cobots open doors to increased productivity, improved workplace safety, and greater adaptability in business operations with advancements in AI and human-robot interaction on the horizon, cobots are set to play an even more significant role in the future of robotic process automation.

For those seeking professional assistance or specialised expertise in dealing with Robotic Process Automation, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our extensive selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Contact Us

Contact Us