Products & Services Industry Guides

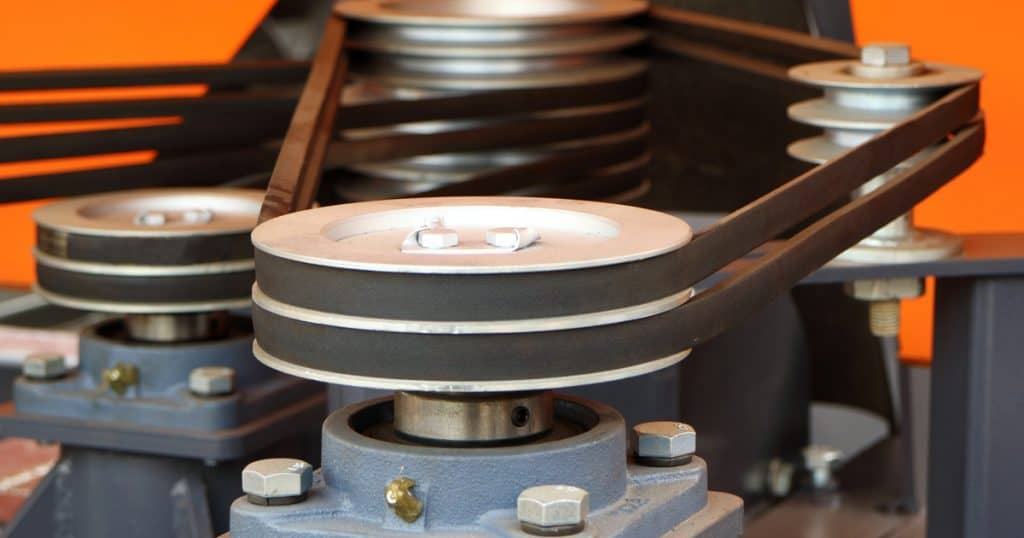

V-belts are important for transferring power in industrial machines for pumping systems, HVAC systems and mining equipment, amongst others.

This makes them an efficient and adaptable component needed for your machine.

However, even the most efficient mechanical parts are prone to wear and failure over time.

While you cannot maintain a pristine condition for your V-belts because they will wear out over time with each use, understanding the failure symptoms and implementing solutions early can help you from frequent and premature breakdowns.

This article will discuss symptoms of v-belt failure in machines and offer solutions to keep operations running smoothly.

Neglecting a belt will cause its abilities to falter and slip, leading to premature failure that could disrupt your operation.

Examples of common premature failures are load-carrying failure and edge cord failure.

When a V-belt is unable to withstand the designed weight, load-carrying failure happens, resulting in premature failure.

Excessive stretching, cracking, or tearing of the belt's material commonly causes this type of failure.

Symptoms:

A sign of cracks, tears or fraying along the length of the belt.

The belt grooves or ribs have significant wear or damage.

Visible distortion or elongation of the belt.

When the reinforcement materials of the V-belt deteriorated, the belt lost its reinforcement strength and broke prematurely.

Symptoms:

Separation of cord at the edges of the belt.

The distribution of wear signs is uneven.

Significant stretching is visible on belt grooves or ribs.

The constant transfer of power between shafts will definitely show an inevitable sign of wear for the V-belt over time.

Similarly, ijedr.org also added that signs of wear can be caused by the influence of environmental conditions such as extremely high or low temperatures during an operation.

However, it is important to monitor any abnormal signs of wear to prevent the V-belt from deteriorating and failing.

Symptoms:

Stiff or hard on the sidewalls of the belt.

Bottom wear that are more excessive as compared to other parts.

Cracks or splits on the belt surface.

Reduce Overloading: Distribute loads evenly across multiple belts or consider upgrading to a higher-rated belt if necessary.

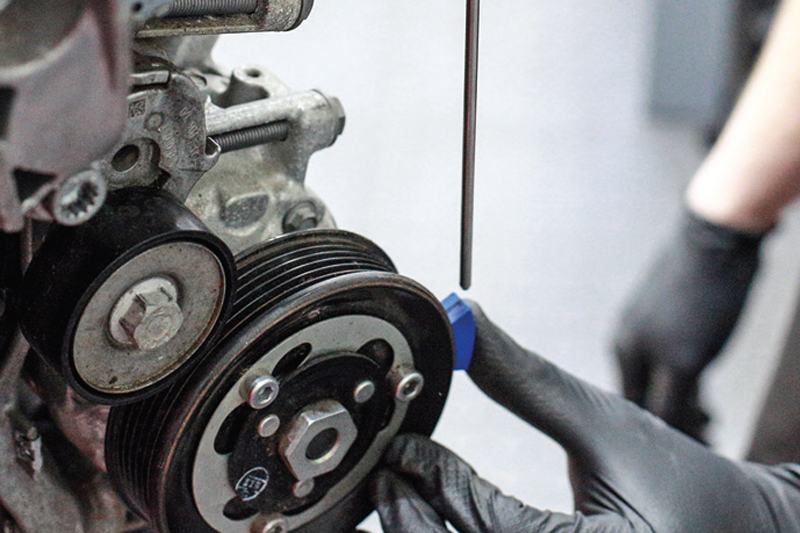

Inspect Pulleys and Sheaves: Check for worn or damaged pulleys that may cause uneven loading on the V-belt.

Optimise Tensioning: Use tension gauges or tensioning tools to adjust belt tension within recommended levels based on manufacturer guidelines.

Address Misalignment: Misaligned pulleys can cause edge cord failure because of increased stress on the belt's edges.

Inspect Pulley Grooves: Smooth out any imperfections in the pulley grooves or consider using belt guides to prevent edge wear.

Use belt guard: Protect the V-belt from damage by using a belt guard. This will prevent it from touching rough surfaces, making it more vulnerable to damage.

Address Misalignment and Tension: Misaligned pulleys or improper tensioning can cause abnormal wear patterns on V-belts. Address these issues promptly to ensure even wear across the belt's surface.

Check the environment: Extreme heat, humidity, or chemicals can make V-belts wear out faster. Implement measures to mitigate these conditions or use specialised belts designed for challenging environments.

Correct Belt Type: Use V-belts specifically designed for the application's operating conditions and environment. Different belt materials and constructions offer varying levels of resistance to wear, ensuring optimal performance and longevity.

In conclusion, addressing challenges related to V-belts is essential for maintaining smooth operations and minimising costly downtime in industrial settings.

Additionally, recognising when you need professional services can further enhance belt performance and longevity.

SLSPRO experts help diagnose and fix tricky V-belt problems, offering valuable insights to solve issues effectively.

You can also browse our extensive V-Belt selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Explore our innovative range of automotive belts, including V-belts, fan belts, and ribbed belts, designed for efficiency and performance in various industries.

Find Out MoreExplore our innovative range of automotive belts, including V-belts, fan belts, and ribbed belts, designed for efficiency and performance in various industries.

Find Out More

Contact Us

Contact Us