Maintaining chain and sprocket systems is crucial for the smooth operation and longevity of machinery. They work together to transfer power efficiently, and regular maintenance ensures that they continue to perform optimally. Neglecting maintenance can lead to reduced performance, costly repairs, and even safety hazards. In this blog, we will explore the best practices for chain maintenance, how to inspect and replace sprockets, and signs of wear and tear that indicate when it's time to replace your chain and sprockets.

Best Practices for Chain Maintenance

- Regular Cleaning: The foundation of effective maintenance is keeping your chain clean. Dust, dirt, and grime can accumulate over time, increasing friction and wear. Using a soft brush or rag with a degreaser is advised to gently scrub the chain, ensuring you reach every nook and cranny. After cleaning, rinse the chain thoroughly with water and allow it to dry completely. Moisture can lead to rust, so it's important to ensure the chain is dry before applying a lubricant.

- Lubrication: Lubricants are vital for reducing friction and increasing the life of your chain. Apply a high-quality lubricant, preferably one designed specifically for your type of chain ensuring even coverage along the entire length. Over-lubricating can attract dirt and debris so ensure not to overdo it. A good rule of thumb is to apply lubricant and then wipe off any excess with a clean cloth. Regular lubrication intervals depend on usage and environmental conditions, so be sure to adjust accordingly.

- Proper Tensioning: Maintaining the correct chain tension is essential for optimal performance. Having a chain that is too loose or tight can result in unfavourable situations. The former can slip and the latter can cause excessive wear on both the chain and sprockets. To check tension, refer to the manufacturer's specifications. Adjust the tension as necessary using the tensioning mechanism, and regularly re-check it during routine maintenance.

- Environmental Considerations: Environmental factors play a significant role in the maintenance of chain and sprocket systems. If your equipment operates in harsh conditions, such as extreme temperatures, wet environments, or areas with a lot of dust, you may need to increase the frequency of your maintenance. It is advisable to use protective covers to shield your chain from debris and moistures. Additionally, be mindful of the lubricants you choose; some are better suited for certain environments than others.

- Routine Inspections: Incorporating regular inspections into your maintenance routine is beneficial. When conducting your inspections, look for signs of wear or damage, such as rust, cracks, or abnormal stretching. Inspect the chain for any signs of binding or stiffness, which can indicate that it needs cleaning or lubrication. The sooner you catch potential issues, the less likely they are to develop into more significant and unavoidable problems.

How to Inspect and Replace Sprockets

- Visual Inspection: A simple visual inspection can provide a wealth of information about the condition of your sprockets. Look for worn or chipped teeth, which can negatively affect the chain's performance. If the teeth appear pointed or have noticeable wear patterns, it may be time for a replacement. Additionally, check for any signs of rust or corrosion that could weaken the sprocket.

- Check alignment: For efficient operations, there must be proper alignment between the sprocket and the chain. Misalignment can cause uneven wear and lead to premature failure. Use a straightedge or alignment tool to ensure the sprockets are properly aligned with the chain. If you find any misalignment, adjust the sprocket position or the chain tension as necessary.

- Measurement of Teeth: Over time, sprocket teeth can wear down and this leads to decreased performance. Using callipers or a micrometer to measure the thickness of the teeth against the manufacturer's specification. If the teeth are significantly worn, it's best to replace the sprocket to prevent the damage to the chain.

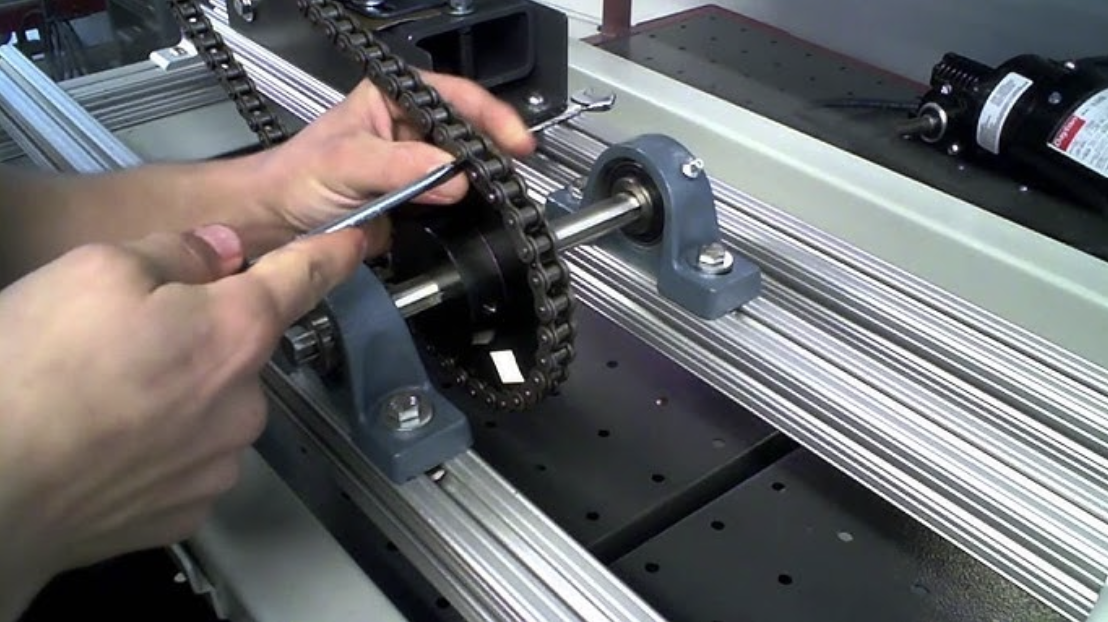

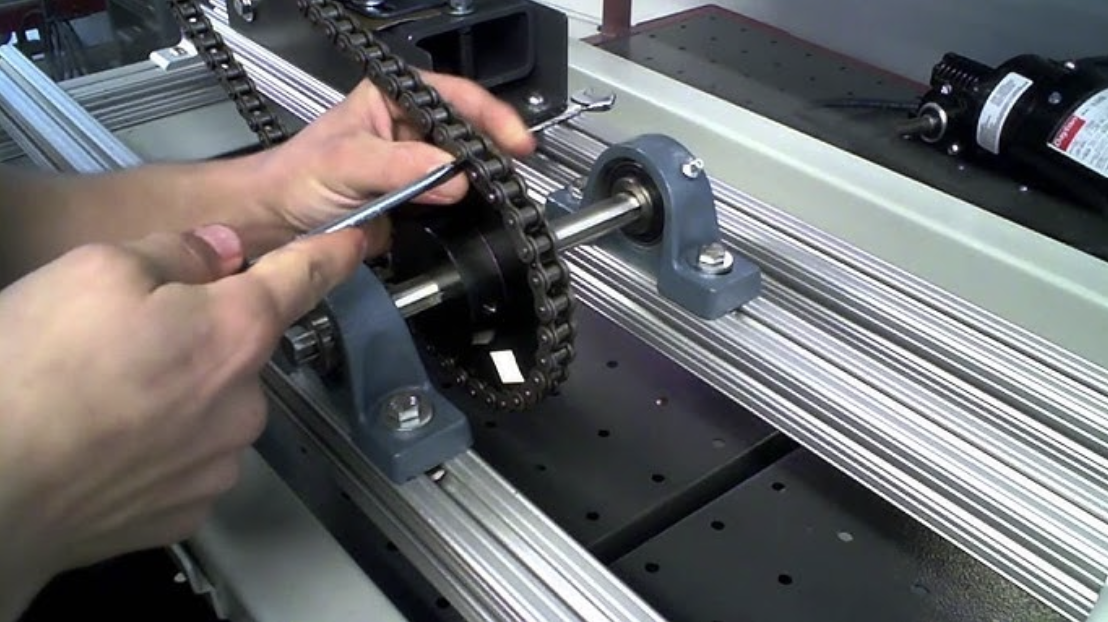

- Replacement Process: If you determine that a sprocket needs replacement, gather the necessary tools, such as wrenches and a socket set. Start by removing the old sprocket, ensuring that you note the position of any spacers or washers. Once the old sprocket is removed, install the new one, ensuring it is correctly positioned or tightened. After installation, recheck the chain tension and alignment to ensure optimal performance.

- Sprocket Material Considerations: When replacing sprockets, consider the materials of the sprockets being installed. Options include steel, aluminium, and plastic, each with its own sets of drawbacks and advantages. For example, steel sprockets are robust and durable, while aluminium is lighter and provides better performance in certain applications. Choose the materials that best suits your specific requirements and operation conditions.

When Should you Replace Your Chain and Sprockets

- Visible Damage: One of the most apparent signs that it's time to replace your chain and sprockets is visible damage. Check for cracked links on the chain, broken teeth on the sprockets, or any bent components. If you notice any of these issues, immediate replacement is necessary to avoid further damage and ensure safe operation.

- Excessive Noise: An increase in noise levels during operation can be an early warning sign of wear or misalignment. Listen for unusual sounds like grinding, rattling, or squeaking. If you hear any of these noises, it's essential to inspect the system closely to identify the root cause and address it before more significant issues arise.

- Increases slippage: Frequent chain slippage can indicate a stretched chain or worn sprocket teeth. If you find that the chain is slipping off the sprockets, it's time to inspect both components. A chain the continuously slips can lead to further wear and potential damage to your machinery, so timely replacement is crucial.

- Decreased Performance: A noticeable drop in performance, such as reduced power transfer or slower speeds, can signal that maintenance or replacements are required. If your machinery is not performing as it should, it's worth checking the condition of your chain and sprockets. Regular performance evaluations can help catch issues early and maintain optimal efficiency.

- Chain Stretch: Over time, chains can stretch, leading to poor engagement with the sprockets. Regularly check the chain for elongation by measuring the distance between a set number of links. If the measurement exceeds the manufacturer's specified limit, consider replacing the chain.

Regular maintenance of your chain and sprocket systems is essential for longevity and performance. By adhering to best practices such as routine cleaning, proper lubrications, and frequent inspections, you can significantly extend the life of these components. Understanding how to inspect and replace sprockets, along with recognising signs of wear and tear, allows for proactive care that prevents costly repairs and ensures the reliability of your machinery.

Incorporating these maintenance tips into your routine not only enhances the efficiency of your systems but also provides peace of mind, knowing that you're taking the necessary steps to keep everything running smoothly. So invest the time in proper maintenance, and your chain and sprocket systems will reward you with improved performance and longevity.

For those seeking professional assistance or specialised expertise in dealing with chains and sprockets, SLSPRO stands as a reliable partner.

SLSPRO experts offer comprehensive services and provide tailored solutions and

specialised services to meet the unique needs of clients across various industries.

You can also browse our extensive

chains and sprockets selections on our website.

Get in touch with us for professional help and greater operational efficiency today!

Hubungi Kami

Hubungi Kami